The thickness of an underfloor heating system is one of the most important variables in the design phase. It directly influences thermal comfort, the responsiveness of the system and the thermal inertia of the structure.

In new buildings, it can be managed with greater flexibility, while in renovations it often represents a decisive design constraint. Correct assessment of the thickness allows you to avoid problems related to overlaps on thresholds, constraints with internal clear heights or incompatibility with existing flooring.

How to define the thickness of the floor system

Thickness refers to the total vertical dimension of the entire radiant stratigraphy. This includes: vapour barrier, insulation panel, pipes, covering screed and surface finish. The total thickness depends on various factors, such as the thickness of the insulation panel, the diameter of the pipes and the type of screed used.

Technical regulations and functional limits impose a minimum threshold for the thickness of radiant systems. Low-thickness systems allow thicknesses of down to approximately 28 mm (e.g. the V-ERRE0 system), ensuring the effectiveness of the system thanks to the use of low-inertia screeds. It is important to remember that reducing the thickness can result in lower thermal inertia, which must be balanced by careful adjustment of the system.

Typical stratigraphy of a radiant system: differences between V-ERRE and V-ERRE0

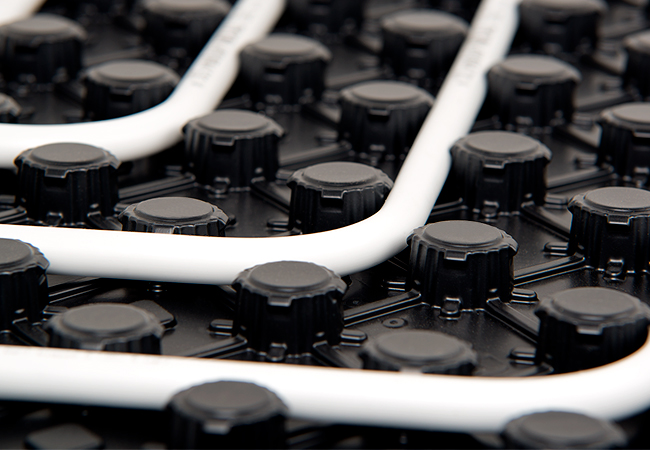

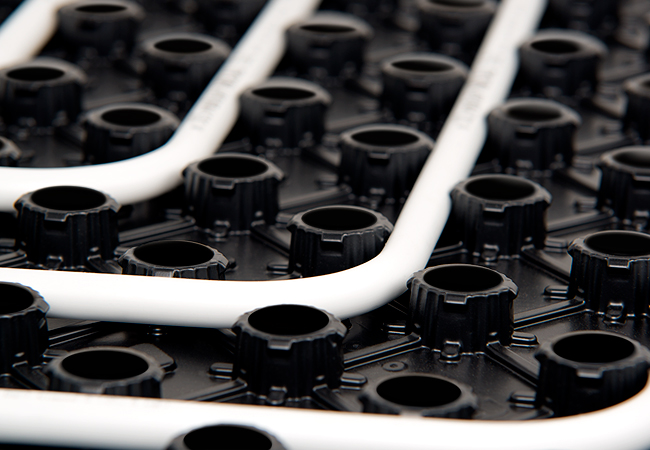

A standard stratigraphy includes, in order: the substrate (possibly treated with primer), a vapour barrier, the insulating panel (often embossed), the pipes anchored in the panel, a covering screed and the final flooring. The embossed panel significantly affects the overall thickness, both due to its relief and to the control of the pitch and housing of the pipes.

The V-ERRE system is in the standard range of radiant systems, with panels of varying thickness depending on requirements. When installed with traditional screed, it is a system suitable for new buildings or renovations with sufficient height margins. However, it can be combined with self-levelling screeds to reduce installation space and create a system with low thermal inertia.

Designed for projects with strict structural constraints, the V-ERRE0 system allows the creation of systems with minimal stratigraphy where, unfortunately, it is not possible to accommodate the thickness of the insulation. The panel is designed to accommodate pipes with a small diameter and can be completed with specific high-conductivity screeds. The entire package can be less than 25 mm thick, allowing installation without demolition and maintaining excellent comfort performance. In this case, low-thickness levelling compounds are the only possible solution to ensure proper functioning and prevent any downward heat loss.

Screed thickness: function, types, technologies

The screed acts as a cover, mechanical support and thermal diffuser. There are two main types: traditional screeds (thicker and with greater inertia) and low-inertia screeds (thinner, for reactive systems). The V-ERRE and V-ERRE0 systems are compatible with both solutions.

Greater thickness promotes thermal inertia: the environment maintains its temperature for longer, but the system response is slower. Conversely, a thin system responds more quickly to commands and is ideal for intermittent use.

In renovations, compliance with internal clear heights and structural constraints sometimes requires the choice of low-thickness systems. In some cases, depending on the conditions of the site, it is also possible to lay the system on top of the existing flooring, improving room temperature control with minimal space requirements.

The overall thickness of the system must also be assessed in relation to the final flooring. Parquet, porcelain stoneware and vinyl have different thicknesses and mechanical characteristics, which affect thermal performance. It is essential to provide expansion joints, compatible adhesives and to comply with the drying times of the screeds.

Regulatory requirements and other considerations

Regulations set minimum requirements for materials, thicknesses and performance. The thickness must ensure the protection of the pipes, adequate thermal transmittance to the environment and compliance with system certifications. CE marking (mandatory) and laboratory tests help to select the most suitable materials.

Low-thickness systems allow for quick and non-invasive installation, with reduced activation times. However, they require careful design to avoid efficiency losses, especially in the presence of insulating finishes.

The choice of thickness for an underfloor heating system is therefore a “strategic” decision. It must be calibrated on a project-by-project basis, taking into account the existing structure, intended use, finishes and expected performance. Knowing how to manage thicknesses correctly allows you to combine comfort, efficiency and sustainability, both in new buildings and renovations.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek