PEXAL

THE MULTILAYER SYSTEM OF EXCELLENCE

DOCUMENTS AND RESOURCES

| Multilayer System | L02-572/6 |

| Pexal: multilayer piping system for water supply | L02-913/4 |

| Supply systems accessories | L02-913/4 |

| PEXAL | T02-287 |

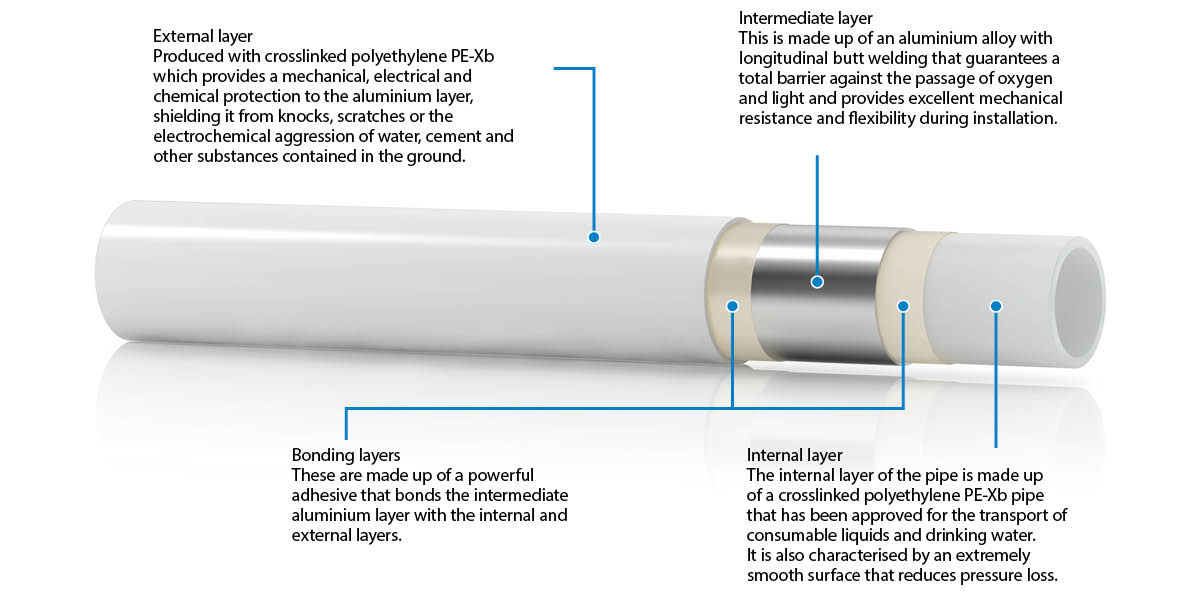

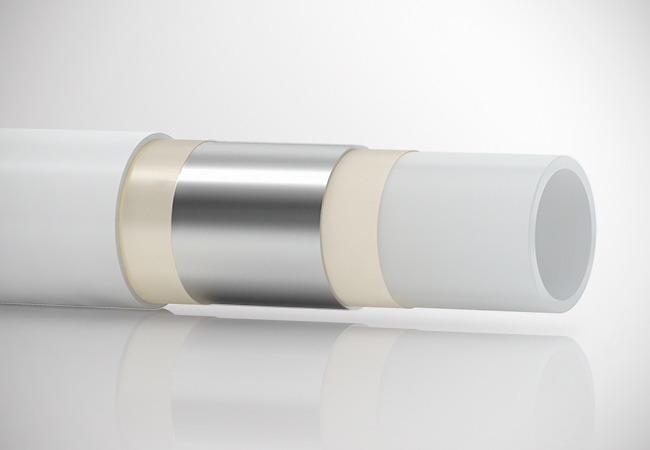

Pexal is the multilayer pipe system made of cross-linked polyethylene and butt-welded aluminium for water conduction compatible with all Valsir fitting lines.

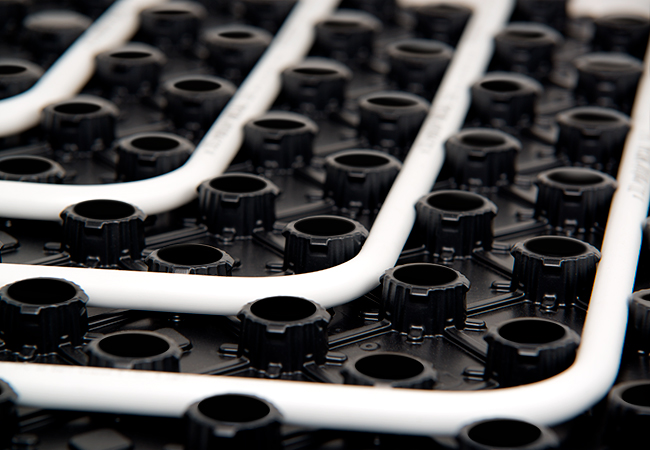

With Pexal it is possible to create hot and cold drinking water distribution systems, heating and cooling systems, compressed air systems and, in general, industrial installations.

The advantages of synthetic materials and aluminium

The prerogative of multilayer piping is to exploit the winning properties of several materials, the performance of which is combined to achieve performance which is otherwise unattainable using plastic or metal piping systems.

ADVANTAGES OF

THE PEXAL SYSTEM

RESISTANT TO CORROSION

The high resistance to corrosion, building materials and major chemical compounds allows the Pexal system to be used for a variety of civil and industrial applications.

EXCELLENT FLEXIBILITY

The combination of cross-linked polyethylene and aluminium guarantees excellent flexibility during bending (even by hand) and long-term shape stability.

SOUND INSULATION

The elasticity of cross-linked polyethylene provides excellent vibration absorption and therefore excellent sound insulation.

REDUCED PRESSURE LOSS

The extremely smooth internal surface, as well as preventing the formation of deposits such as lime scale, ensures reduced pressure loss also with the passage of time.

GUARANTEED FOR 50 YEARS

The system has a guaranteed product durability of at least 50 years, during which time its use is permitted at pressures of 10 bar and maximum operating temperatures of up to 95°C.

COMPLETE RANGE

The range of fittings (available in both metal and technopolymer materials), accessories and related equipment is extremely wide and allows any requirement to be covered.

BARRIER AGAINST OXYGEN AND LIGHT

The butt welded aluminium layer acts as a total barrier against oxygen and light, which in plastic pipes would otherwise favour algae growth and the corrosion of the metal parts that make up the system.

NON-TOXIC MATERIALS

The system is made up of materials that are completely non-toxic and is certified for the transport of consumable fluids and drinking water.

THERMAL EXPANSION

The thermal expansion that normally affects the pipe in operation is about 8 times less than that of plastic pipes and is comparable to that of metal pipes.

IDEAL SOLUTION IN AREAS SUBJECT TO EARTHQUAKES

Pexal is the ideal solution in areas subject to earthquakes thanks to the excellent mechanical properties such as flexibility and the capacity to alleviate vibrations.

WIDE RANGE OF DIAMETERS

Pexal is an extremely comprehensive range, including multilayer pipes with diameters ranging from 14 mm to 110 mm.

LIGHTWEIGHT

The Pexal pipes are extremely light compared to metal pipes: the weight is 1/3 of that of a corresponding copper pipe and 1/10 of that of a corresponding steel pipe.

An environmentally sustainable solution

The Pexal system is manufactured from fully recyclable materials that can be reused at the end of the product life. The manufacturing processes employed are also energy-efficient and have a reduced ecological impact.

In fact, Valsir embraces Green Building principles, with a view to respecting the environment and preserving natural resources.

We wanted to make available the EPD declarations certifying the environmental impact related to the production of the water supply systems consisting of the Pexal multilayer pipes and the Pexalbrass, Bravopress and Pexal Easy fitting systems according to the complete LCA analysis, i.e. 'cradle-to-grave'.

To reach this figure, we monitored and optimised not only the production phases, but considered the product life cycle in its entirety: today we can say that the Pexal system is a 'champion of sustainability', from the extraction of raw materials to the disposal of the product itself.

Choose Pexal for your project and get credits for Green Procurement sustainability protocols (e.g. LEED V4)!

How is Pexal produced?

Aluminium

There are different methods for the production of multilayer pipes and they differ mainly in the technology used in welding the aluminium pipe. It can be formed by overlapping, overlapping and welding, or by butt connection and welding.

The latter is the technology chosen by Valsir because it guarantees uniform thickness over the entire circumference, greater resistance to pressure and curvature, consistent mechanical characteristics, better adhesion values with the binding layers and a total barrier to oxygen.

Cross-linked polyethylene

The crosslinking process can be performed using different technologies, recognised by International standards and identified with the follow methods: A (peroxides), B (silanes), C (radiation), D (azo-compounds); the method used is indicated together with the abbreviation for the material, thereby obtaining PE-Xa, PE-Xb, PE-Xc, PE-Xd.

There is a lot of conflicting information in the market as to which is the best technology; however, it is not the type of crosslinking process that determines the quality of the pipe but the capacity to produce it in compliance with all the relevant quality standards which are applied to all four of the aforementioned crosslinking methods.

You might not know, but Pexal is also...

Easy and economical to lay

Thanks to their excellent mechanical characteristics the Valsir multilayer pipes can be bent in order to reduce the number of fittings needed, thereby obtaining an economic advantage.

Fire resistance

Valsir multilayer pipes have been tested at the CSTB (Departement Securite Structures et Feu) approval institute with test report No. RA09-0093 in which it is noted that the system achieves fire resistance class M1 when coated with specific heat-insulating sheaths.

Resistant to legionella treatments

Compared to metal pipes, Valsir multilayer pipes have a greater resistance to chemical compounds and may undergo treatments (eg. superchlorination shock) for several years without being damaged.

Focus

Our in-depth reports for professionals, about Valsir products and regarding drainage systems and water conduction, underfloor heating and cooling, and flush cisterns

WATER SUPPLY

Contamination from Legionella in plumbing systems: risks of infection and prevention measures

Infections from Legionella are marking an increase all over the world due to...

WATER SUPPLY

Pexal: an excellence system based on multiple layers

Pexal is a multilayer pipe, consisting of two separate materials: a metal and...

MARITIME SYSTEMS

An ideal partner for the marine sector

The idea of developing hydraulic solutions for naval installations is not...

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek