PP Ecoforte

HIGH-STRENGTH PIPES FOR THE SEWAGE SYSTEM

DOCUMENTS AND RESOURCES

| PP-HM system for sewers | L02-814/3 |

| PPEcoforte: PP-HM system for sewers | L02-913/4 |

| Equipment and accessories of sewer systems | L02-913/4 |

| PPECOFORTE | T02-314 |

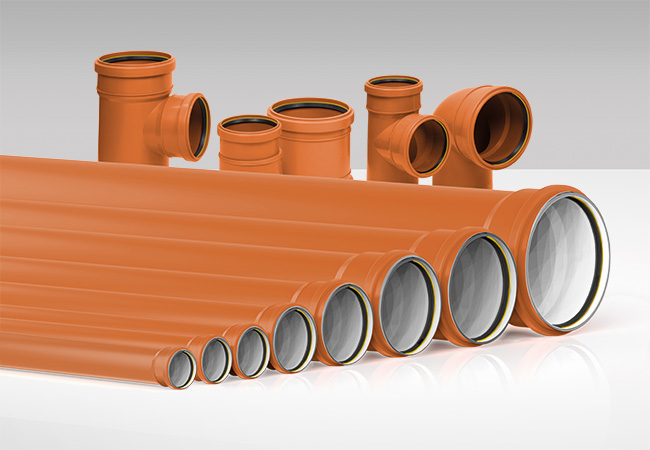

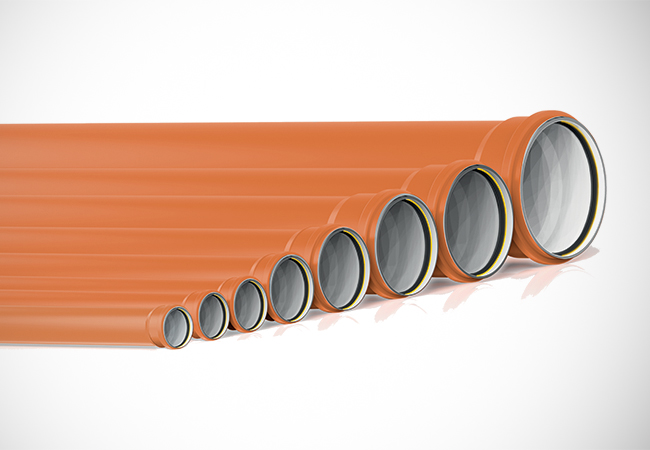

PPEcoforte is a high-strength pipe system with a triple-layer wall made of high-modulus polypropylene (PP-HM), suitable for underground, non-pressure sewage pipelines, in RAL 8023 on the outside and RAL 9003 on the inside.

To complete the system, moulded and thermoformed fittings are available in compact PP-HM in RAL 8023. The use of PP-HM makes it possible to create a high-performance system in terms of resistance to loads, bending, and internal and external abrasion.

The PP Ecoforte system complies with the UNI EN 13476 standard and includes a wide range of accessories to create an efficient sewage system.

ADVANTAGES OF

PPECOFORT

LONG LASTING

The entire system of pipe, fittings and elastomeric gasket is designed to last.

DYNAMIC RESISTANCE

Resistance to breaking and crushing under dynamic stress.

MECHANICAL STRENGTH

Even at low temperatures the handling of pipes and fittings does not cause problems with ruptures, as required by EN 1411.

FLEXIBILITY

Annular flexibility that allows the pipe to withstand high pressures caused by underground laying and the passage of vehicles.

WIDE RANGE

The wide range of diameters (from 110 to 500 mm) allows use in all types of construction: residential, road or industrial.

JOINT TYPES

Socket joint system with elastomeric ring type BL UNI EN 681 or on request with Forsheda Din-Lock® type locked gasket.

Fittings

PPEcoforte sewer fittings for underground non-pressure pipelines are made for conveying:

- Discharges of civil and industrial waste waters (white, black and mixed water)

- Agricultural industrial discharges and waste water in general

- Valsir fittings are manufactured from compact PP-HM with mineral filler added.

Product dimensions and geometry are guaranteed in accordance with UNI EN 13476.

Most fittings are made using moulding technology, while larger diameters are made by thermoforming.

Joint systems

The joining of pipes and fittings is done by push-fit coupling using two types of gaskets:

- Standard: pre-mounted single-lip elastomeric seal (SBR), type BL (UNI EN 681 standard)

- Upon request: elastomer gasket made of two-component (TPV-E and PP) type Forsheda 582 Din-Lock® with triple lip

The locked gasket coupling system allows for easier insertion and ensures the stability of the gasket when engaging even large pipe diameters.

Both joint systems absorb ground movements.

Forsheda Elastomeric Gasket 582 Din-Lock®

- Gasket stability during pipe joining operations.

- Easy insertion thanks to the design and pre-lubrication of the gasket.

- Perfect water tightness once installed in compliance with UNI EN 1277 at a pressure up to 0.5 bar.

- Ability to absorb ground movements or vibrations even after installation (caused by static, hydrostatic and dynamic loads).

When two pipes are joined, the rubber sealing element is designed to deform to create a seal, acting on both the joint and the socket.

Both jointing systems absorb ground movement.

Focus

Our in-depth reports for professionals, about Valsir products and regarding drainage systems and water conduction, underfloor heating and cooling, and flush cisterns

SEWAGE SYSTEMS

Sewerage systems: reliable technologies for a safe environment

In a constantly evolving urban context, sewerage systems play a key role in...

SEWAGE SYSTEMS

The ideal sewerage system: innovation, resistance and sustainability

A sewerage system is the essential infrastructure for the collection and...

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek