BRAVOPRESS

TECHNOPOLYMER PRESS FITTINGS

DOCUMENTS AND RESOURCES

| Multilayer System | L02-572/6 |

| Bravopress: crimp fittings in technopolymer | L02-913/4 |

| Supply systems accessories | L02-913/4 |

| BRAVOPRESS | T02-159 |

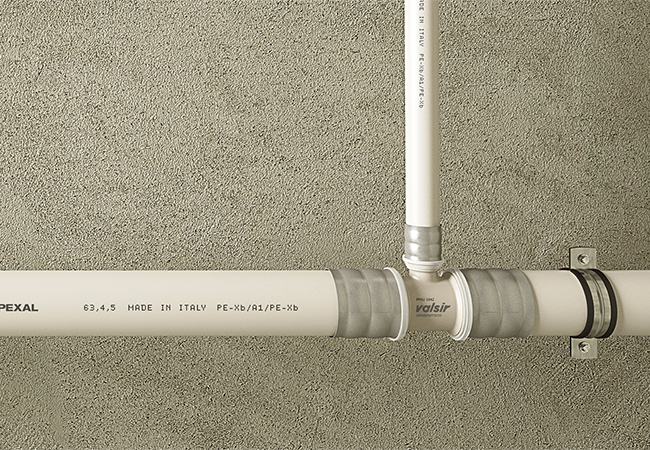

Bravopress is the press fitting system made of technopolymer (PPSU), a plastic material with excellent mechanical and corrosion resistance.

It is combined with Pexal and Mixal multilayer pipes and Thermoline, and can be used for water supply, heating, cooling and industrial installations.

ADVANTAGES OF

BRAVOPRESS

NO OXIDATION

Complete lack of oxidisation or corrosion.

MULTI-PRESS PROFILE

Compatible with a broad range of pressing profiles (H, TH, U, C).

SUITABLE FOR DRINKING WATER

Bravopress press fittings are certified for the transportation of drinking water.

CHEMICAL RESISTANCE

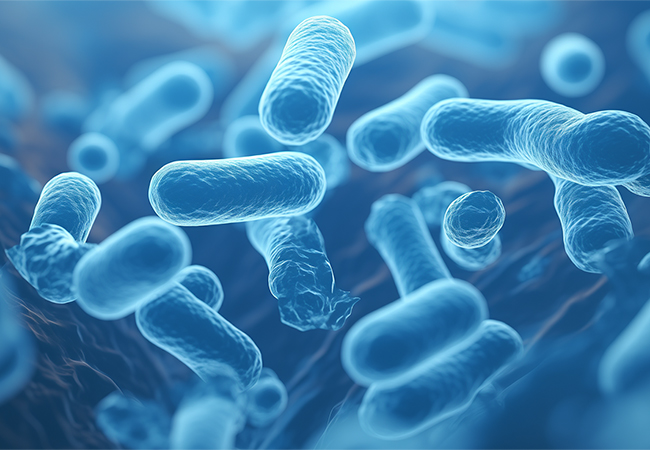

Chemical resistance to the main substances dissolved in water, constantly in contact with pipes and fittings. Excellent resistance to legionella treatment with hypochlorite.

WIDE RANGE

Bravopress fittings are available in a wide range of diameters, from 16 to 63 mm.

EXTREMELY LIGHT

Construction in technopolymer makes Bravopress fittings extremely light.

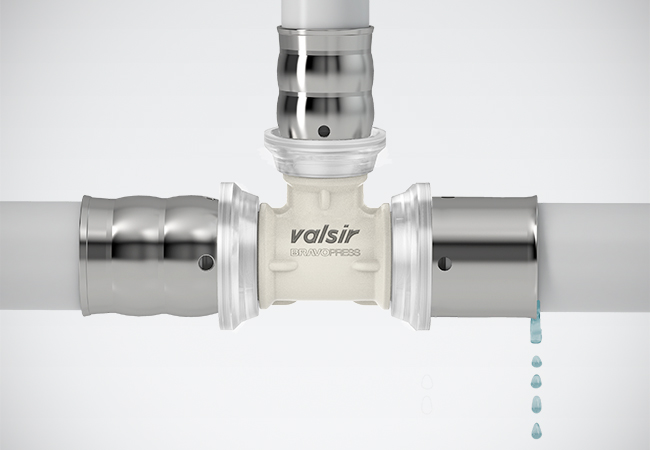

UNPRESSED LEAKING

Leak signalling during system test in the case of non pressed fittings on diameters from 16 mm to 32 mm (for pressures between 0.5 and 2 bar).

SIMPLIFIED ASSEMBLY

Better control of the pipe insertion on the fitting thanks to the transparent bottom ring and inspection holes on the bushing.

INSURANCE COVERAGE

Bravopress fittings are covered by a 10-year insurance policy from the date of purchase, which covers any damage caused by manufacturing defects.

An environmentally sustainable solution

The Bravopress fittings are manufactured from fully recyclable materials that can be reused at the end of the product life. The manufacturing processes employed are also energy-efficient and have a reduced ecological impact.

In fact, Valsir embraces Green Building principles, with a view to respecting the environment and preserving natural resources.

We wanted to make available the EPD declarations certifying the environmental impact related to the production of the water supply systems consisting of the Pexal multilayer pipes and the Pexalbrass, Bravopress and Pexal Easy fitting systems according to the complete LCA analysis, i.e. 'cradle-to-grave'.

To reach this figure, we monitored and optimised not only the production phases, but considered the product life cycle in its entirety: today we can say that Bravopress is a 'champion of sustainability', from the extraction of raw materials to the disposal of the product itself.

Choose Bravopress for your project and get credits for Green Procurement sustainability protocols (e.g. LEED V4)!

Quick and easy installation

Bravopress is a fitting system that combines the outstanding mechanical properties of polyphenylsulphone with the advantages of a pressed joint of the steel sleeve.

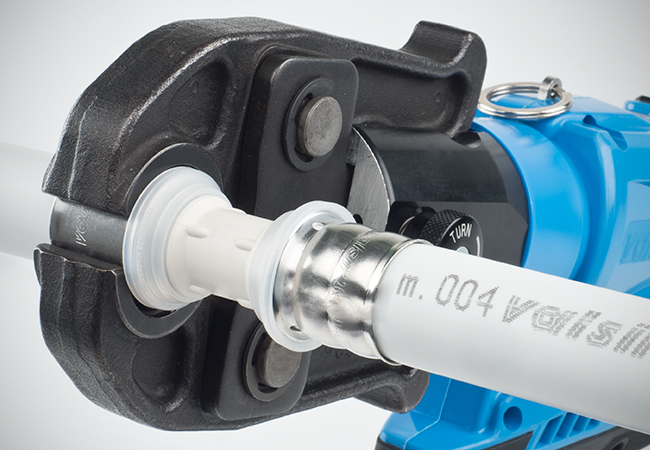

As with the brass press fittings, the Bravopress fittings have been designed to reduce installation times by using a portable pressing machine equipped with specific pressing jaws.

Multi-press

The Valsir press fittings, both in brass and in technopolymer, are termed “multipress” as they can be used with the various pressing profiles most widely used in the market.

This is an important advantage: the installer can use the Pexal Brass and Bravopress multipress fittings produced by Valsir, regardless of the type of tool they possess.

Polyphenylsulfone

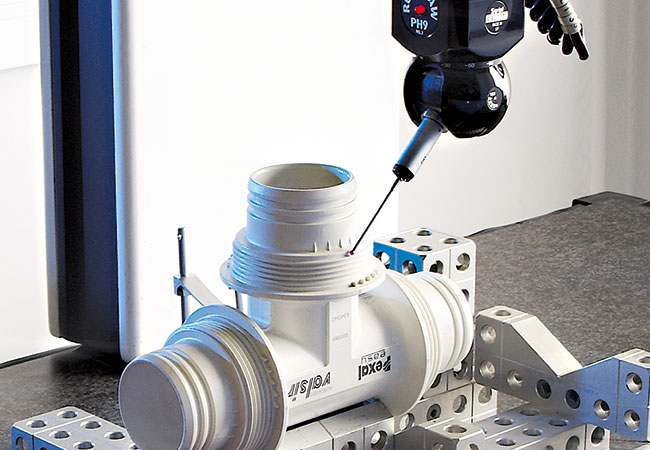

Polyphenylsufone (PPSU) is a technopolymer that provides exceptional mechanical performance, used mainly in automotive applications, in the aerospace and medical industry, and which in recent years is now widely used in the plumbing industry.

This material is characterised by high mechanical strength - even at high temperatures - and resistance to major chemical compounds.

The mechanical properties such as tensile strength, modulus of elasticity and resistance to ageing, are far superior to those of normal polymers.

Tools

Reliability, durability and quality are the characteristics that distinguish the range of Valsir tools used in the installation of the Bravopress fittings; these products were designed taking in consideration the suggestions of our most trusted installers and made with only top quality materials.

Pressing machines up to a diameter of 110 mm, belling machines up to a diameter of 75 mm, pipe cutters, multi-diameter countersinks, and systems for manual or mechanical bending of pipes are just some of the equipment that complements and completes the entire range.

Focus

Our in-depth reports for professionals, about Valsir products and regarding drainage systems and water conduction, underfloor heating and cooling, and flush cisterns

WATER SUPPLY

Contamination from Legionella in plumbing systems: risks of infection and prevention measures

Infections from Legionella are marking an increase all over the world due to...

SUPPLY SYSTEMS

The advantages of PPSU in a press fitting

High mechanical resistance, even at high temperatures. Impressive chemical...

WATER SUPPLY

Multilayer fittings: technical guide and comparison of Valsir systems

In the world of modern plumbing, fittings for multilayer pipes are at the...

VIDEO

Bravopress - The advantages of plastic polymers in a press fitting

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek