In the world of modern plumbing, fittings for multilayer pipes are at the heart of connections between pipes for water, heating, air conditioning and industrial applications. Fittings are not just accessories: they determine the efficiency, durability and safety of the system.

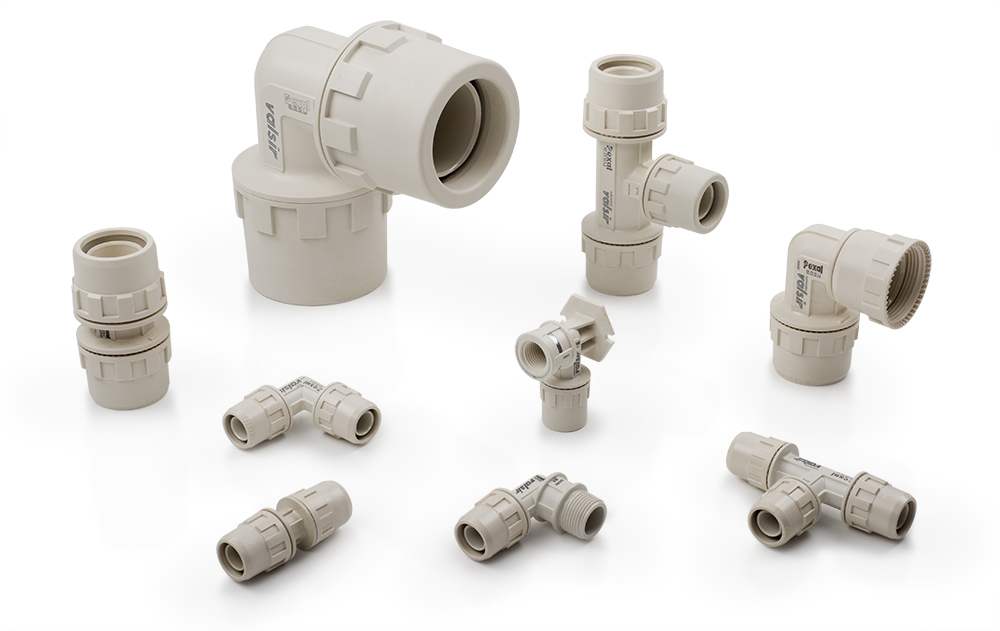

Our catalogue offers four different solutions for multilayer pipe fittings, each designed for specific design requirements: Pexal Brass, Bravopress, Pexal XL and Pexal Easy. In this article, we examine the unique features of each system, comparing their technical and application advantages.

Why multilayer fittings are essential

Fittings connect multilayer pipes (made of cross-linked polyethylene and aluminium), ensuring hydraulic tightness, chemical and mechanical resistance and, above all, suitability for transporting drinking water.

All our fittings stand out for:

- Long-term reliability: they withstand high pressures and temperatures, as well as chemicals and mechanical stress.

- Installation flexibility: they allow quick and secure connections with or without special equipment.

- Environmental compatibility: all Valsir products are made from recyclable materials, in line with Green Building principles.

Overview of the different Valsir fitting families

We have developed a wide range of solutions for our Pexal and Mixal multilayer pipes, divided into 5 main families:

Brass press fittings: Pexal Brass

Pexal Brass fittings are made of brass with a stainless steel bushing and a transparent bottom ring that improves pipe insertion. Main features:

- Multi-press compatibility (U, TH, H, C profiles)

- High mechanical resistance

- Certification for drinking water transport

- Optimal sealing thanks to double gasket

When and where to use

- Hot and cold domestic water distribution

- Traditional heating systems

Pexal Brass fittings incorporate the ‘unpressed leaking’ system, which allows you to identify any missed pressings during system testing.

Technopolymer press fittings: Bravopress

Made of PPSU (polyphenylsulfone), which makes them extremely resistant to many chemical compounds, making them an excellent choice for systems subject to sanitisation treatments such as anti-legionella treatments:

- Excellent chemical and thermal resistance

- Compatibility with chlorine shock treatments

- Total hygiene for hospital and healthcare systems

Other features

Bravopress fittings also support different press profiles and are equipped with a “unpressed leaking” system for detecting any missed presses during system testing.

Modular technopolymer fittings: Pexal XL

A modular system designed for large systems, allowing hundreds of configurations to be created by combining a few simple elements, which are easy to assemble without special tools.

Its potential at a glance:

- Combination of standard modules (elbows, tees, reducers) that allow for the creation of customised configurations with great versatility

- Quick installation without special tools thanks to the collar closure system

- Prefabrication on a bench to facilitate work at height

It is ideal for large systems because it is designed for use with multilayer pipes from Ø110 mm.

Pexal XL is suitable for:

- Shopping centres, hotels, hospitals

- Complex systems with water distribution or multi-storey buildings

Full bore fittings: Pexal Easy

The special internal geometry increases water flow and reduces pressure drops. This family of fittings avoids any reduction in the passage section, resulting in a 30% higher flow rate than traditional fittings.

Other strengths:

- Total absence of oxidation

- Fittings can be dismantled and reused (except in countries where this is not permitted, such as France)

- 100% anti-slip closure system

It is ideal for all applications, including the most sensitive (such as the hospital sector) or those that are more difficult due to environmental conditions (shipbuilding, in direct contact with sea water).

The fittings are installed using the ‘cup’ technique for multilayer pipes, which requires special equipment.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek