The Ventilation Branch Fitting, also known as VBF, was invented by engineer Fritz Sommers in the 1960s. His goal was to solve a typical problem in multi-storey buildings: simultaneously managing wastewater drainage and ventilation of the waste pipe network without using two separate columns. The VBF system is a technical innovation that combines the functions of waste disposal and ventilation in a single column.

For decades, the idea was not put into practice due to the technical difficulties associated with the use of metal materials. With the advent of plastics such as polyethylene and polypropylene, the Ventilation Branch Fitting became a concrete and high-performance reality, capable of revolutionising the design of plumbing systems in residential and other applications.

What is a waste pipe branch fitting?

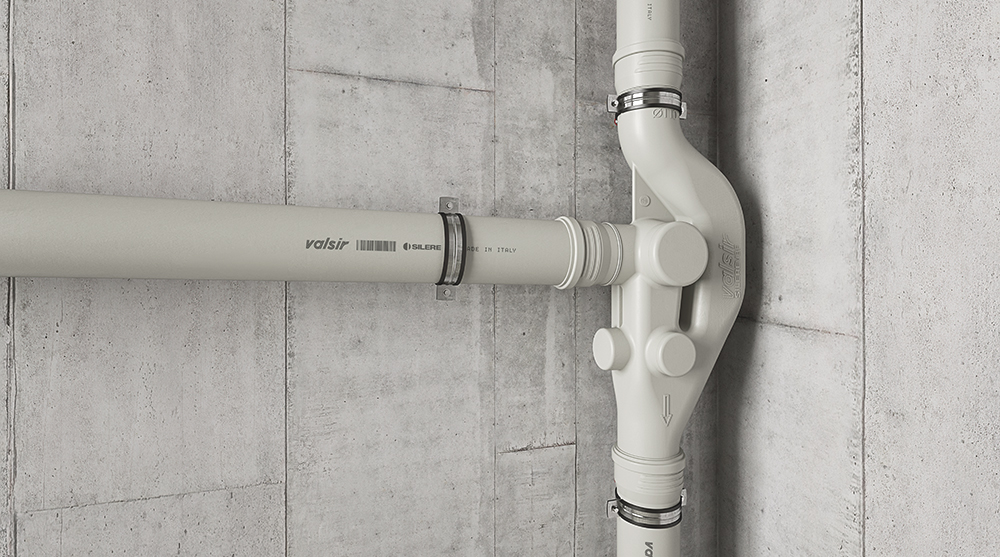

The Ventilation Branch Fitting is a complex geometric fitting that allows the connection of multiple horizontal branches to the main vertical column, managing waste and ventilation in an integrated manner. The operating principle is based on the physical and dynamic separation of the flows coming from different branches, ensuring controlled mixing and avoiding turbulence and pressure variations that could compromise the functionality of the siphons.

The VBF has six inlets: three upper ones for large waste flows (e.g. toilets) and three lower ones for smaller waste flows (e.g. washbasins, bidets). The internal structure comprises three functional areas: a diversion chamber, a mixing chamber and a deflector, each with the specific task of reducing the flow velocity, stabilising the pressure and ensuring optimal ventilation of the network.

Advantages of VBF over traditional systems

One of the main advantages of systems with VBF is the possibility of eliminating the parallel ventilation column. This means simplified design, less space occupied and a significant optimisation of the materials used.

The integration of multiple functions in a single waste pipe results in savings in terms of pipe diameters, fittings, brackets and installation time. In addition, space is freed up in technical shafts, which is valuable in buildings with high-density systems.

The VBF is ideal for structures where simultaneous use of services is large. The internal pressures in the riser remain low even in the event of multiple waste flows, ensuring hydraulic stability and system durability.

The Ventilation Branch Fitting in system design

A waste pipe with VBF can achieve flow rates of up to 13 l/s with diameters of 110 mm, far exceeding the limits of systems with primary (4 l/s) or parallel (5.6 l/s) ventilation. With the same cross-section, a VBF pipe can serve up to 100 standard bathrooms, compared to 16 with traditional systems.

The performance of the VBF has been tested according to regulatory criteria (e.g. UNI EN 12056-2) and clearly exceeds that of classic systems. Benefits include lower pressures, no need for special siphons, and lower risk of trap backflow or emptying.

Practical applications of the waste column with VBF

The VBF is ideal for use in high-rise buildings, residential towers and mixed-use complexes, where pressure containment and compactness of the systems are fundamental requirements.

In hospitals, hotels and sports facilities, there is a large number of simultaneous users of the sanitary facilities. Ventilation Branch Fitting waste pipes allow for optimal flow management, increasing the reliability and quietness of the system.

Hydraulic and acoustic performance of systems with VBF branch fittings

The internal shape of the Ventilation Branch Fitting reduces turbulence and depressions, preserving the seal of the water traps even in the presence of highly discontinuous waste flows.

In silent waste systems (such as Silere or Triplus), the use of VBF enhances acoustic performance thanks to the smooth management of waste water, which flows without jolts or sudden disconnections.

VBF and materials

Polyethylene (HDPE) offers high chemical and thermal resistance, making it ideal for industrial and technical buildings. However, installation requires welding, increasing time and costs.

Valsir also offers the Ventilation Branch Fitting in polypropylene, integrating it into high acoustic performance systems such as Blackfire, Triplus, PP3 and Silere. Installation is simpler, with socket and gasket connections, without compromising performance.

HDPE is preferred for heavy-duty technical installations, while PP stands out for its ease of use and excellent soundproofing. The choice depends on the intended use of the building and the project requirements.

In healthcare and hotel environments, PP offers the best compromise between acoustic comfort and speed of installation. For industrial waste systems, HDPE remains the optimal choice.

Principles for installing the Ventilation Branch Fitting

The maximum installation distance between two branch fittings is 6 m. It is essential to avoid reductions in diameter along the column and to check the need for a ‘pressure relief loop’.

This is a secondary bypass circuit, mandatory in some configurations, which serves to balance the pressures at the base of the waste pipe. It ensures that the lowest appliances are not subjected to overpressure.

If the total flow rate is less than 5.2 l/s and the height difference between the extreme points of the pipe is less than 12 m, the loop can be omitted. This allows greater flexibility in small to medium-sized buildings.

Special waste pipe configurations

Vertical deviations must follow precise geometries so as not to alter the flow. For displacements of more than 1 m, an intermediate vertical section or decompression loop is required.

Multiple columns can be joined downstream of their respective loops, maintaining a minimum distance of 1 m between connections. This allows for centralised management of the manifold without compromising functionality.

Branches must not exceed a maximum length of 8 m if unventilated (6 m with WC) or 20 m if ventilated. Slopes range from 1% to 5% depending on the type of connection.

If the branch serves more than one appliance or exceeds the length limits, a secondary ventilation circuit must be provided, connected to the column via a 45° branch.

Maintenance and inspections

It is advisable to provide for at least one inspection every five floors and at the pressure relief loop to facilitate cleaning and periodic checks.

VBF branch fittings must be installed in accessible technical shafts.

The Ventilation Branch Fitting (or VBF branch fitting) is a special fitting that allows both the waste water flow and the ventilation of the waste pipe to be managed simultaneously. This eliminates the need for two separate pipes and the ventilation pipe can simply be omitted.

FAQ

What distinguishes the VBF from a traditional waste branch?

The VBF integrates waste and ventilation in a single structure, reducing diameters and complexity compared to systems with separate columns.

In which cases is a ‘pressure relief loop’ mandatory?

When the flow rate is large (>5.2 l/s) or the height difference between waste outlets is greater than 12 m, the loop is essential for system safety.

Can the Ventilation Branch Fitting be used in renovations?

Yes, especially in cases where you want to upgrade a traditional system and improve its performance without creating new shafts.

What is the average lifespan of a VBF system?

If correctly installed and maintained, a VBF system can exceed 50 years of useful life.

Do soundproofed systems also improve hydraulic efficiency?

Yes, because the integration of VBF with sound-absorbing materials and structures improves both the acoustic comfort and the fluid dynamics of the system.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek