Modern plumbing relies on multilayer pipes because they have become synonymous with reliability, versatility and durability. The technologies and materials used today in the production of plumbing pipes make it possible to meet a wide range of system requirements – from private homes to large industrial facilities – with a single product that guarantees high performance, health safety and dimensional stability.

Multilayer pipes were created with this objective in mind: to overcome the limitations of single-material solutions, such as plastic or metal pipes, by combining their best qualities in a single structural element.

What distinguishes multilayer plumbing pipes from others?

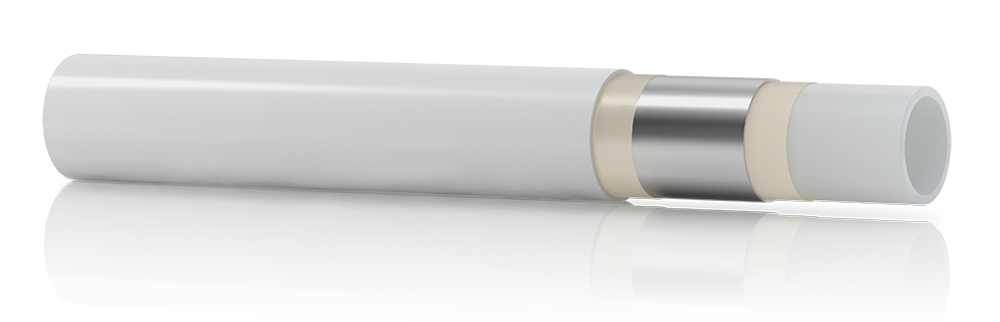

Unlike traditional pipes, a multilayer pipe has a composite structure made up of several materials that work in synergy. The plastic layers – in particular cross-linked polyethylene – guarantee hygiene and chemical resistance, while the aluminium layer provides strength, an oxygen barrier and low thermal expansion. This means that multilayer hydraulic pipes:

- Are more resistant to high pressures and temperatures

- Maintain their shape even after bending

- Offer excellent sound insulation and durability

- Are not subject to corrosion or bacterial proliferation

These characteristics make them the ideal choice for complex plumbing systems, where technical requirements are particularly stringent.

What are the most common applications for Pexal and Mixal pipes?

Both Pexal and Mixal are used in a wide range of installations. Pipes for plumbing systems are no longer a generic component: they must be integrated into networks that often involve domestic hot water, heating, cooling and, increasingly, industrial distribution.

Pexal is particularly appreciated in centralised systems and large water networks, where a wide range of diameters, mechanical strength and long-term stability are required.

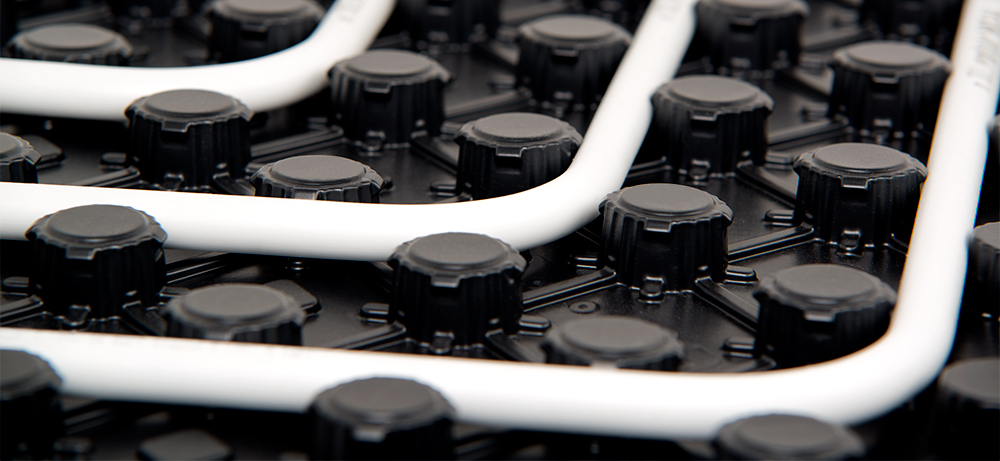

Mixal, on the other hand, stands out for its extreme flexibility, which makes it particularly suitable for radiant floor, wall or ceiling systems, where speed and ease of installation are essential.

Both systems are suitable for:

- Domestic water distribution (cold and hot)

- Radiator or radiant heating systems

- Cooling

- Industrial and compressed air applications

How do these pipes perform over time?

Life cycle is one of the decisive parameters when choosing a pipe for a plumbing system. Both Pexal and Mixal have a certified durability of at least 50 years, even under demanding operating conditions: pressures up to 10 bar and temperatures up to 95°C.

Their performance over time is also stable in terms of shape and expansion: unlike plastic pipes, multilayer pipes undergo less deformation with temperature changes and do not require an excessive number of anchoring points.

This means simplified maintenance, a tidier system and lower long-term running costs.

What role does the quality of materials play in a multilayer hydraulic pipe?

It all starts with the raw material. Valsir multilayer pipes are made with:

- PE-Xb cross-linked polyethylene, which ensures abrasion resistance and mechanical durability

- Butt-welded aluminium, for structural uniformity and oxygen tightness

- High-adhesion adhesives, for a stable chemical bond between the layers

- External coatings in PE-Xb or PE-HD, depending on the model, for impact resistance and chemical protection

The production processes – such as vacuum steam cross-linking – guarantee consistent and controlled quality on every metre of pipe.

How do Pexal and Mixal differ?

Although they share many of the same qualities, the two systems are optimised for different needs:

- Pexal is designed for structured and professional installations, even with diameters greater than 32 mm. It is available in bare, insulated or corrugated versions to suit any installation context: exposed, concealed or buried.

- Mixal, on the other hand, is the most immediate and flexible solution for small and medium-sized systems. Its strength lies in its quick installation, even manually, and its ability to adapt to small spaces without the need for complex fittings.

The choice is not only technical, but also design-related: it depends on the type of system, the configuration of the rooms and the level of customisation required.

How are multilayer plumbing pipes installed correctly?

The installation of pipes for plumbing systems can vary greatly depending on the context: new or existing buildings, exposed or concealed installation, climatic and seismic conditions, architectural or structural constraints. One of the main reasons why Pexal and Mixal systems are so popular is that they adapt perfectly to all these situations.

Valsir multilayer pipes can be:

- Installed in view, with a significant reduction in the number of collars required compared to traditional plastic pipes

- Installed concealed, thanks to protection against abrasion and chemical reactions with plaster and cement

- Buried, if protected by corrugated sheathing

- Used in seismic areas, thanks to their ability to absorb vibrations and micro-movements

During installation, it is essential to comply with the rules on bending, minimum radii, distances between brackets and thermal insulation methods to avoid condensation or dispersion.

The pipes are compatible with thermal insulation sheath technologies, ideal for energy efficiency, and with anti-UV coatings, essential for outdoor installations or in environments exposed to sunlight.

What guarantees do they offer in terms of certification and safety?

When it comes to plumbing systems, material certification is not a formality: Pexal and Mixal comply with EN ISO 21003, which defines the technical requirements for multilayer piping systems intended for the transport of hot and cold water in both sanitary and heating applications.

The certifications cover:

- Pressure and temperature resistance

- Minimum durability of 50 years

- Absence of release of undesirable substances

- Organoleptic tests on drinking water

- Complete product traceability

The marking along the pipe includes all essential information: product code, application class, nominal pressure and temperature, regulatory reference, certifications obtained, diameter and thickness.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek