In radiant floor systems, pipes are responsible for distributing the heat transfer fluid. Their quality, type and compatibility with the rest of the system have a decisive influence on efficiency, safety and comfort. The pipes work in synergy with insulating panels, screed and the control system to ensure a uniform and stable temperature in the rooms.

Types of pipes for floor systems

The main categories of pipes for radiant systems include single-layer and multi-layer solutions. The former, made of PE-X or PE-RT, are characterised by their simple construction and low cost, but have greater thermal expansion and lower dimensional rigidity. Multi-layer pipes, on the other hand, combine the advantages of plastic and metal pipes, ensuring better performance in terms of stability and durability.

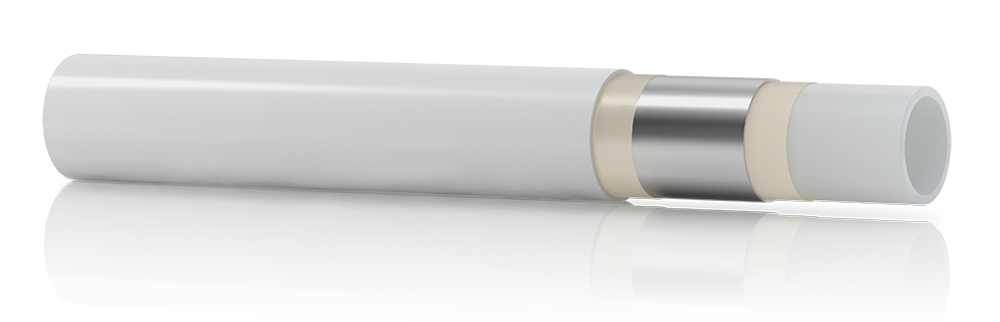

Multilayer pipes for floor systems are composed of several layers of material: an internal structure in cross-linked polyethylene, a core in aluminium welded using the latest TIG or laser technology, and an additional external coating in polyethylene. This configuration allows for:

- Prevention of corrosion and algae formation in systems thanks to a total oxygen barrier

- Reduce the plastic memory of the pipe and facilitate installation

- Reduce linear thermal expansion compared to plastic pipes

- Improve thermal conductivity and therefore heat exchange with the screed

Thermal and mechanical performance of multilayer pipes

Thanks to their composite structure, multilayer pipes offer an optimal combination of pressure resistance, high temperature resistance and heat transmission. They can operate effectively in systems with low-temperature fluids (e.g. 30–40 °C), such as those powered by heat pumps. Their low thermal expansion makes them particularly suitable for installation in complex spaces, avoiding tension at critical points in the circuit.

Mixal pipes are designed with an aluminium core wrapped in two layers of cross-linked polyethylene. This gives the pipe:

- A shape memory that facilitates installation

- High flexibility, useful for changes in direction

- Resistance to pressures up to 10 bar and temperatures up to 95 °C

Thanks to their technical characteristics, Mixal pipes maintain uniform heat exchange and improve surface temperature homogenisation.

A PE-Xb alternative

Thermoline pipes, made of PE-Xb, are a valid alternative to multilayer pipes. They have good mechanical resistance and an oxygen barrier made of a layer of EVOH. They are particularly suitable for systems with complex layouts and continuous operating conditions. Compatibility with the main fastening systems and insulating panels makes them versatile and easy to install.

Design choices

The choice of pipe diameter for underfloor heating systems affects heat output, fluid velocity and pressure drops. The most commonly used diameters in residential applications are 16 and 17 mm. Smaller diameters (e.g. 12 mm) allow for installation in confined spaces, but require careful design to avoid excessive pressure drops. Larger diameters, on the other hand, improve efficiency over larger areas and are safer in terms of possible pipe blockages due to debris or other objects.

Pipes used in floor heating and cooling systems must have several key characteristics: on the one hand, they must guarantee long-term functionality and durability, and on the other, they must be easy to install. In addition, the choice of pipes affects the performance of the system itself: for this reason, it is essential to identify the most suitable solution, aiming for the best possible construction quality.

Multilayer pipes are designed to integrate effectively with both embossed and smooth panels. In embossed panels, the embossing guides and holds the pipe in place at regular intervals, while in smooth panels, clips or guides are often used for anchoring. The right combination of panel and pipe reduces heat loss downwards and optimises heat transmission to the environment.

Pipes for underfloor heating must comply with specific technical standards. The most relevant are:

- UNI EN ISO 21003, which regulates multilayer systems

- UNI EN 1264, specific for radiant floor systems

Functional advantages of multilayer pipes

The use of multilayer pipes for underfloor heating offers numerous functional advantages: reduced thermal expansion, long service life (over 50 years), corrosion resistance, good workability and compatibility with mechanical joints. These characteristics reduce installation times, increase system safety and limit maintenance requirements.

Multilayer pipes are a consistently reliable technical solution for floor heating systems thanks to their strength, versatility and compatibility with modern energy requirements. They are particularly suitable for residential and tertiary applications. Careful selection of the pipe type, diameter and accessory materials is essential to achieve optimal performance over time.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek