Silere represents the ultimate in sound-insulating products for the transport of waste water and rainwater inside buildings.

The system was designed with the goal of reducing to a minimum the noise produced by waste systems due to the vibrations caused by the movement of the waste flow: the pipes and fittings are made of a mix of polypropylene and mineral fillers with the aim of notably increasing the specific weight of the product.

In addition, both pipes and fittings often have fittings with a high thickness, a factor that further contributes to achieving the goal of noise reduction.

An entire soundproofing system

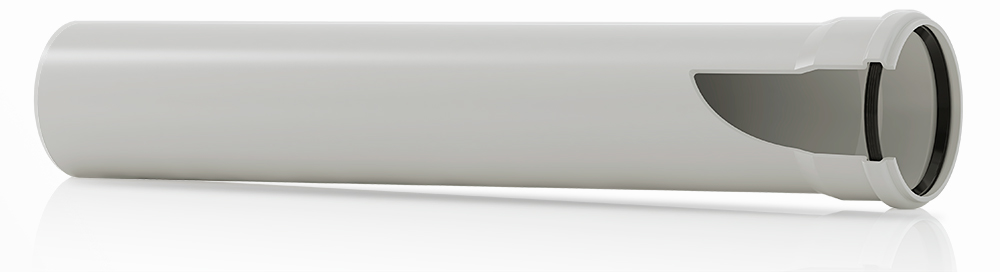

The Silere range extends from a diameter of 58 to 160. The same product can therefore be used for branches for each floor, waste stacks and manifolds. The pipes are extruded in bars from 150 mm up to 3 m in length, in the version with push-fit socket. Production also includes completely smooth 5 m bars without socket, which thanks to the use of coupling fittings make it possible to reduce pipe scrap to a minimum.

The fittings are produced by means of injection moulding. The range is so wide to permit the creation of any system; the system can also be connected to any type of pre-existing pipe in plastic or metal.

Pipes and fittings are connected by means of push-fit socket system.

The push-fit socket with SBR seal has many functions, including to simplify installation. But it especially serves to guarantee hydraulic tightness and to avoid eventual malodorous gas leaks.

The socket also manages the thermal dilation of the pipes: it is proportioned to enable the sliding of the pipe during the operation of the waste system.

Record numbers

Silere has a robust structure highly resistant to mechanical stresses, and can be used without any contraindication even at very cold temperatures down to -20°C.

When it comes to the temperature of the fluids, the limit is 80°C for continuous waste transport and 95°C for discontinuous waste transport.

There is even a very high chemical resistance to the most common substances dissolved in civil and industrial waste water.

Silere is simply the quietest waste solution on the market. The noise of the system is comparable to the rustle of windblown leaves.

Silere has been tested with excellent results at the Fraunhofer Institute in Stuttgart, one of the points of reference in Europe for tests on the acoustics of waste systems. According to the indications of the European standard EN 14366, the tests were made on pipes and fittings with a 110 mm diameter, noting values equal to 6 dB with a capacity of 4 l/s.

The ventilation branch fitting (VBF) deserves special mention; it is a special fitting ideally used for tall buildings or buildings where there is a high rate of sanitary fixtures used at the same time.

The ventilation branch fitting

It was created with the aim of handling high drainage flows, and ensuring proper ventilation of the system, while using a single pipe with a small diameter.

Thanks to the fitting’s special shape - which enables the waste flow to be slowed at each floor of the building and the inlet of waste water from the horizontal branches to be separated from that passing through the vertical pipes - pressures can be considerably reduced and therefore high drainage flows can be achieved without the need for parallel ventilation stacks.

In this way, the number of sanitary fixtures connected to the waste stack can be up to 6 times more than possible with parallel ventilation solutions in the same diameter.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek