Duct banks are composed of a pipe bundle, generally in plastic and embedded underground inside of which run cables: they are used for the creation of cable ducts, for laying fibre optic cables, electrical lines and for telecommunications, etc.

Both due to the number of pipes used and the distance they have to cover, duct banks can be very large: in fact, inspection chambers can even be several kilometres apart from each other.

The cable laying duct bank therefore has the task of protecting the cables on the inside, guaranteeing adequate protection from mechanical stresses, ground moisture and groundwater that might oxidise the cables and damage them irreparably.

How and why was Polimask developed

In conventional installations it is often impossible to ensure watertightness between the duct bank and inspection chamber: infiltrations of water can occur, and if they are substantial enough, they can lead to the flooding of the chamber (and thus preventing access).

In these cases, the only solution possible is for the chamber to be emptied by means of pumping, which carries a significant cost.

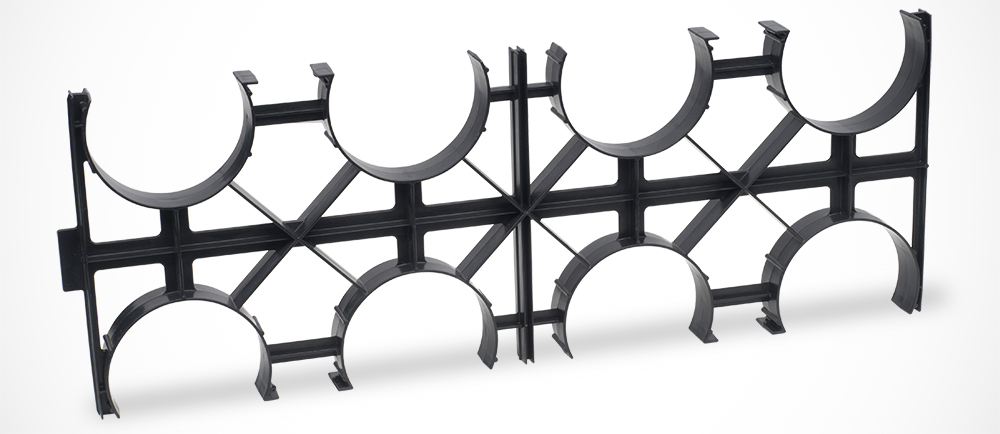

Polimask was developed specifically to solve this type of problem. The characteristics that determine its efficacy include:

- the plastic body (printed in a single piece and created in PP) which prevents water infiltration

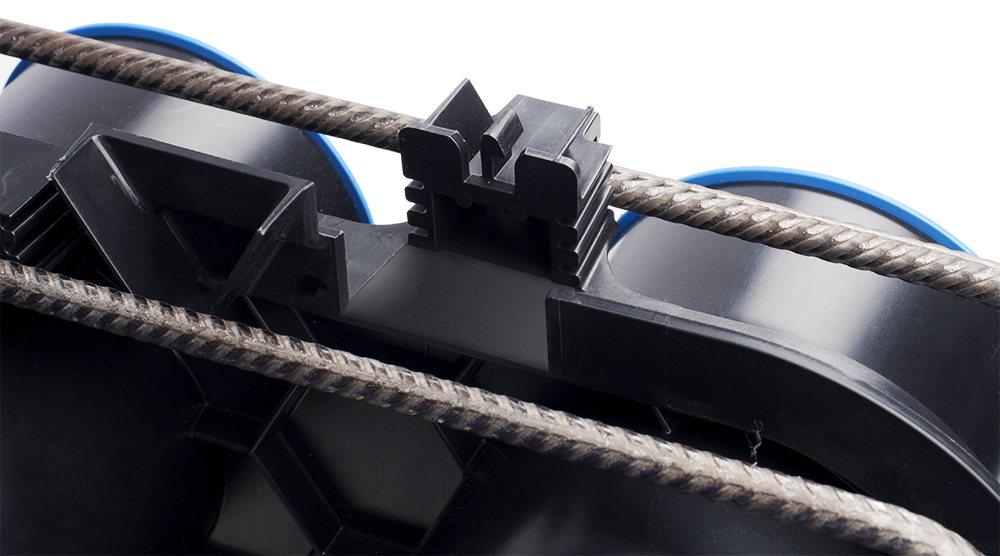

- the 8 connections available, created with a diameter of 110 mm and fitted with sockets for the double sealing element connection

- the bentonite Water-Stop that totally seals the mask unit

- the double steel frame ensuring high resistance to mechanical stresses

All these elements guarantee a perfect watertight connection between the duct bank and inspection chamber.

The advantages of installing Polimask

Compared to a traditional solution, Polimask also makes it possible to reduce installation times because it renders some procedures unnecessary, such as:

- cutting stub pipes, necessary for crossing through walls

- anchoring stub pipes to the framework of the wall, in order to prevent them from being “lifted” by the concrete casting

- adapting the framework to the spacing of the pipes composing the duct bank

In practical terms, this difference translates into an installation time of about 5-10 minutes compared to the 40 minutes usually required.

There are a few other simplifications when installing Polimask: after deciding on the connection stub pipe to use (based on the thickness of the wall), the Water-Stop seal is inserted around the mask in PP, then Polimask is positioned inside the framework of the wall being constructed – by anchoring it with a simple iron wire. The process continues with laying the formworks and pouring the concrete using a vibrator with a 3 cm head to avoid the formation of air pockets that might represent weak spots for the watertightness of the whole system.

Polimask prevents flooding of inspection chambers, which could only be solved by pumping, at considerable cost!

To be pointed out is that several Polimasks can be aligned horizontally or vertically according to the needs of the construction site, in this way taking advantage of the modularity this solution has to offer.

Polimask guarantees the best performance when used in combination with PPEcoforte pipes. Made in high-module polypropylene, they comply with standard UNI EN 13476 and are suitable for laying underground both outside and inside buildings; they are available in the classification from SN 4 to SN 16 and in diameters ranging from 110 to 500.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek