In the heating and plumbing sector, multilayer pipes are the most reliable, efficient and durable solution for domestic water distribution and heating and cooling systems. The success of this technology is based on a simple but powerful concept: combining the strengths of plastic and metal materials to create a pipe that combines strength, flexibility, hygiene and durability.

Composition and structure: the strength of layering

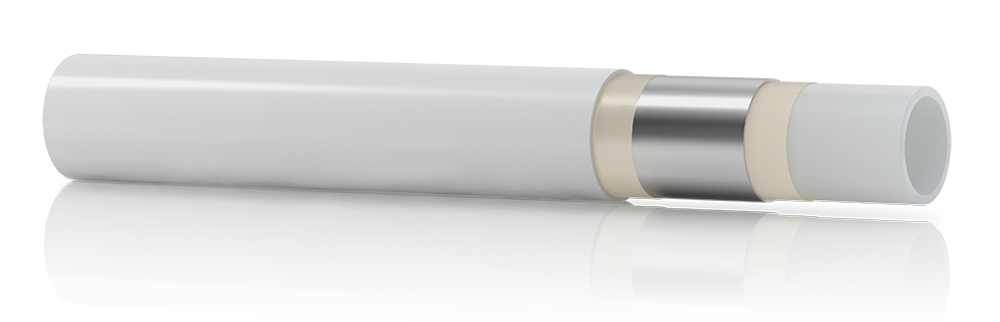

A multilayer pipe is composed of five layers bonded together:

- Inner layer in PE-Xb (cross-linked polyethylene): ensures hygiene, abrasion resistance and surface smoothness

- Internal adhesive: bonds the inner plastic layer to the next metal layer

- Intermediate layer in butt-welded aluminium: provides dimensional stability, oxygen barrier and mechanical strength

- External adhesive: bonds the metal layer to the final coating

- External layer in PE or PE-Xb: protects against impact and chemicals

This intelligent layering achieves performance that no single material could provide, with a perfect balance between flexibility and rigidity.

The mechanical and chemical properties most appreciated by installers

The concrete advantages that professionals find in using multilayer pipes include:

- Resistance to pressures up to 10 bar and temperatures up to 95°C

- Low thermal expansion (about 8 times lower than that of a PE pipe)

- Impermeability to oxygen and light

- Vibration absorption for excellent sound insulation

- Reduced scale formation thanks to the smooth inner surface

- Ease of installation, even in complex spaces and with small bending radii

Multilayer pipe: where it is used and what are the benefits

Multilayer pipes are used in a wide range of plant engineering sectors. In both civil and industrial applications, these pipes offer superior performance for:

Domestic hot and cold water distribution

Certification for the transport of drinking water is an essential requirement. Pexal and Mixal systems are non-toxic, certified and do not release foreign substances, even at high temperatures. Total oxygen impermeability prevents the proliferation of bacteria, contributing to the hygienic safety of the system.

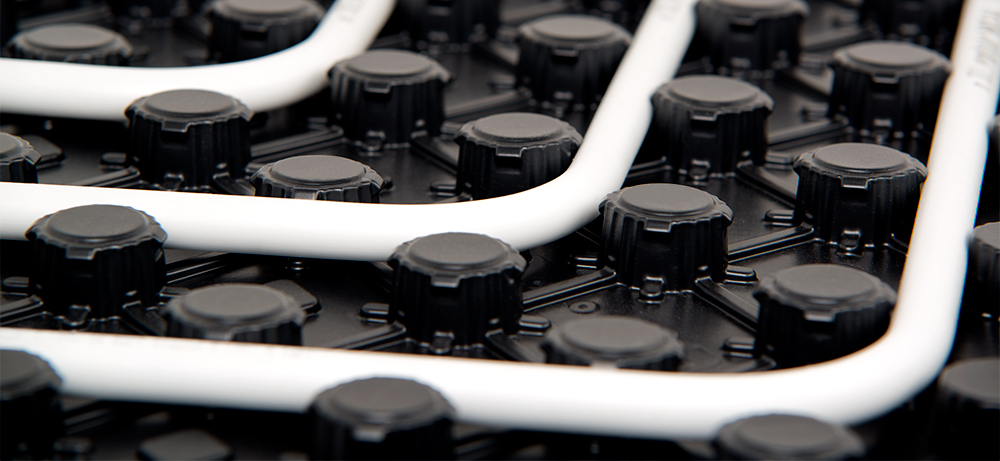

Radiant heating and cooling systems

The dimensional stability and flexibility of multilayer pipes make them ideal for radiant floor, wall and ceiling systems. In particular, Mixal stands out for its extreme manoeuvrability and the ease with which it can be installed on complex routes.

Industrial applications and compressed air

Thanks to their chemical resistance and protection against external agents, multilayer pipes are also perfect for the distribution of compressed air and technical fluids, especially in industrial environments where robustness and durability are required.

Pexal system: technical characteristics, materials and operational advantages

The Pexal system is a well-established benchmark in the professional market for water, heating and industrial systems. It offers scalable solutions with diameters from 14 to 110 mm and numerous variants: bare, coated, in rolls or bars.

Pexal pipe stratification: PE-Xb and butt-welded aluminium

The butt welding of the aluminium ensures maximum mechanical homogeneity and a perfect oxygen barrier. The two PE-Xb layers (internal and external) protect against abrasion, impact and chemical attack, making the pipe suitable even for severe conditions.

Technical specifications and compatibility with fittings and accessories

Pexal is compatible with a wide range of fittings:

- Pexal Brass (press brass)

- Bravopress and Pexal Easy (technopolymer)

- Pexal XL (large diameters)

The system supports temperature peaks of up to 95°C and an operating pressure of 10 bar, with an expected service life of over 50 years.

Performance: strength, durability, lightness

Thanks to its lightness (1/3 that of copper), low roughness (0.007 mm) and resistance to external agents, Pexal allows for quick, safe and long-lasting installations. Its dimensional stability reduces the number of clamps and facilitates installation, even in exposed areas.

Mixal system: flexibility and performance for living comfort

The Mixal system represents the most flexible evolution of the multilayer pipe and is designed specifically for radiant systems. Its structural characteristics make it particularly easy to install even in complex contexts, with curved or articulated routes, as is often the case in floor, wall or ceiling systems.

PE-Xb technology and the qualities of the Mixal pipe

The stratigraphy of the Mixal pipe is similar to that of Pexal but with one important difference: the outer layer is made of high-density PE, while the inner layer remains in PE-Xb, ensuring hygiene and superior mechanical performance. The aluminium core, butt-welded, ensures a complete barrier to oxygen and light, which is essential to prevent the formation of algae.

Why it is the ideal pipe for radiant systems

Mixal is designed to easily adapt to any installation requirement:

- It can be bent manually

- Minimum bending radius equal to 5 times the diameter

- Ability to maintain its shape after bending

These properties drastically reduce the use of fittings and collars, lowering costs and simplifying installation.

Chemical resistance, impermeability and health safety

Mixal is non-toxic, corrosion-resistant and has obtained the most stringent certifications for the transport of drinking water in the main international markets (Italy, France, the Netherlands, England, etc.). Its impermeability to oxygen eliminates the risk of bacterial proliferation, making it ideal for healthcare and public settings.

Differences between Pexal and Mixal: when to choose one or the other

The choice between Pexal and Mixal depends on the type of system and operating conditions. Both systems share excellent structural characteristics, but have specific features that make them more suitable for certain uses.

Pexal is preferable where structural strength and a wide range of diameters are required, while Mixal is the best option where flexibility is a priority.

Considerations regarding installation, compatibility and performance

- Mixal is easier to bend and install on complex routes

- Pexal is ideal for exposed installations and more demanding environments

- Both guarantee a certified lifespan of 50 years, resistance up to 10 bar and operating temperatures up to 95°C

Installation techniques: underground, exposed, concealed

Pexal and Mixal multilayer pipes can be installed in any way:

- Underfloor, thanks to abrasion protection

- Exposed, reducing the number of collars by 40% compared to plastic pipes

- Underground, with special corrugated sheaths

- In seismic areas, thanks to high ductility and vibration absorption

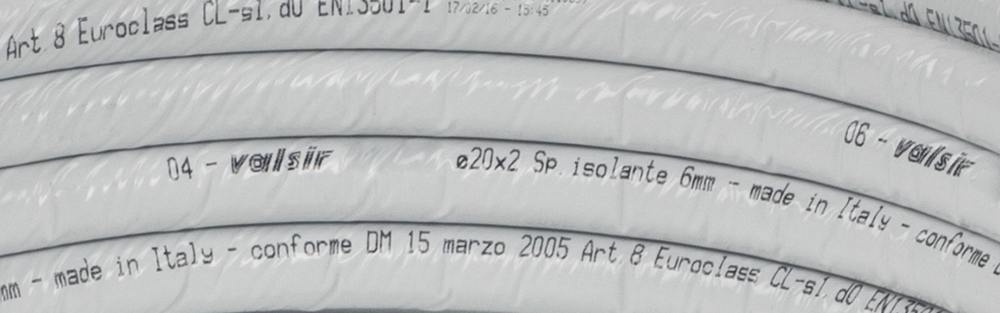

Regulations, certifications and markings: a guarantee of quality and safety

A reliable system cannot ignore regulatory compliance. Pexal and Mixal systems are designed and tested in accordance with EN ISO 21003, the European reference standard for multilayer systems intended for the transport of hot and cold water, heating and sanitary systems.

Compliance with EN ISO 21003

The pipes are certified for all application classes covered by the standard, including:

- Class 1 and 2: domestic hot water

- Class 4 and 5: low and high temperature heating systems

- Operating pressures up to 10 bar

- Peak temperatures up to 95°C

The tests include chemical, mechanical and potability stress tests, carried out regularly by accredited third parties.

Product marking and traceability

Each pipe clearly shows:

- Valsir brand and trade name

- Diameter and thickness

- Class of use and maximum pressure

- Regulatory reference and international certifications

- Progressive measurement

- Production data for traceability

Pexal and Mixal are certified for the transport of drinking water in Italy, Germany, France, Austria, England and many other countries.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek