Complexity is a key characteristic of a construction site, and the bathroom is a perfect example. This is where all the typical systems of a home are concentrated and interconnected: hot and cold water supply, drainage, ventilation, heating, as well as the electrical system and possibly air conditioning.

The installation of these systems involves the coordinated effort of many professionals: the brick layers, plasterer, electrician and plumber. Usually, the work of the teams, all of whom have very different time-frames, has to be coordinated to ensure that delivery deadlines are met. This is often a real challenge in large-scale works.

One of the typical requirements of the work site, then, is to facilitate the progress of the works that can condition the total duration of the installation of the systems.

One of the first solutions introduced was lightweight, plasterboard or wooden walls. This cuts down on the time required for masonry work, but it comes at the cost of a lack of flexibility in the installation of the systems, since a predefined frame structure (typically one post every 60 cm) is by its very nature rather restricting.

In recent years, however, a new approach has been adopted, that of prefabricated technical walls. This is a technologically innovative and complete solution which allows considerable freedom, both architecturally and in terms of system design.

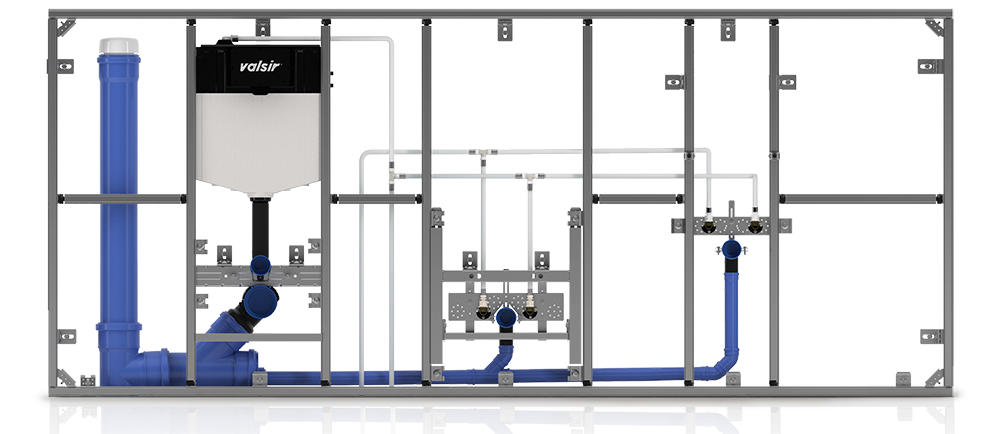

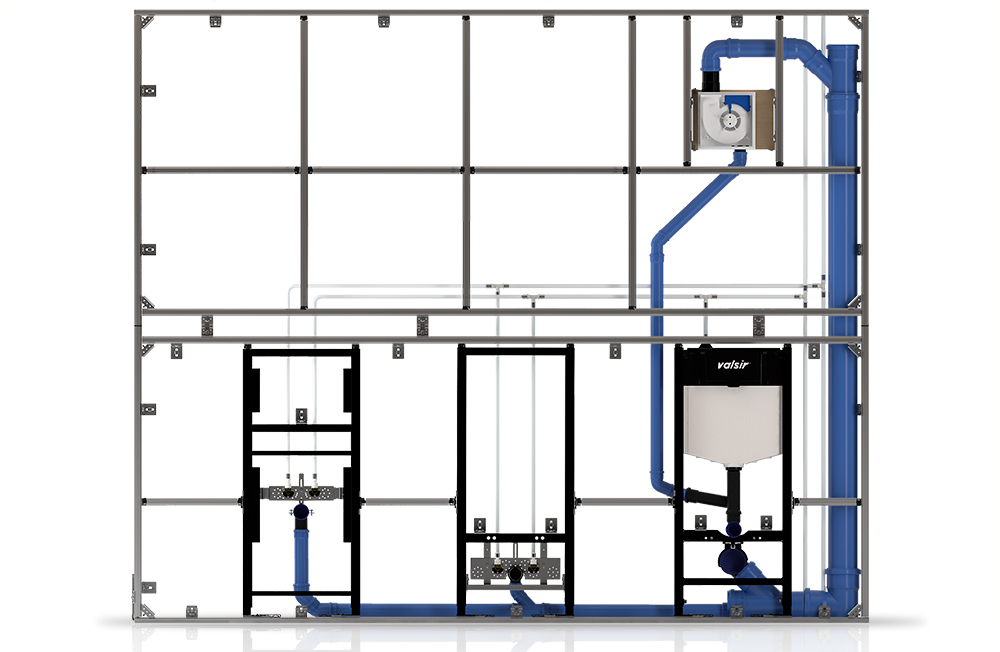

Our solution is the MFV range: “Montaggio Facile e Veloce” or “Fast and Easy Installation”

The main feature of the MFV system is its flexibility, which allows any type of wall (light load-bearing or partition) to be built, containing both the sanitary fixture anchoring structures and the supply and drainage systems.

This way it is possible to prefabricate and transport the bathroom walls - which can be subdivided into modules - considerably reducing plumbing times (these times become independent in relation to the progress of the building site, allowing for a rational co-ordination of interventions).

The modularity of MFV also allows the structures to be broken down only during the transport phase, to be re-coupled at the time of installation. In terms of time reduction, this solution allows a saving of up to 30%, when compared to the system of underground installations.

What about renovation?

The MFV solution is most effective in buildings with a high degree of repeatability (or modularity) of bathroom spaces, such as hotels, hospitals or residential buildings. This is because, as mentioned above, prefabrication greatly simplifies the management of site progress.

But even in the case of renovation, the advantage is obvious, as prefabrication can be carried out directly on the building site, with a specific area for storing the various components and a location for cutting the bars.

But there are other advantages to choosing prefabrication. Testing supply and drainage lines can be carried out in suitably equipped rooms and by qualified personnel, relieving the construction site of this task.

Even after installation, all systems remain fully accessible, both for maintenance and for any subsequent renovation work.

The MFV system allows one person to lay the entire structure and install the sanitary ware, completing the job (excluding finishes) in less than 48 hours!

Lastly, an aspect relating to the design of the bathroom itself: with Revit it is easy to check any possible interference of architectural components with those of the systems before installation actually takes place. This means that we can determine the positioning of risers and outlets with the utmost precision and efficiency, and avoid unexpected problems or complications during assembly later on.

All that remains is to take care of the finishes, and the bathroom is ready.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek