One of the most keenly felt aspects in the building world today is that of living comfort, i.e. all those factors that determine domestic well-being, such as temperature, air quality, acoustics and brightness.

Speaking of acoustics, a key role is reserved for waste systems: it is increasingly important to ensure a low noise level, especially in densely populated environments.

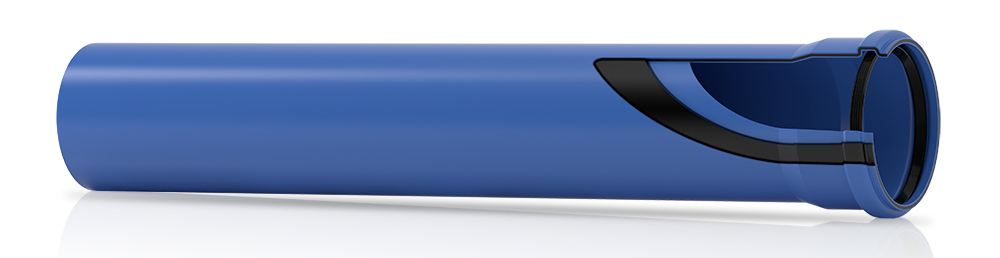

Triplus is one of the leading products among the soundproof drainage systems. It is a plug-in system used for the evacuation of low- and high-temperature effluents, for drainage network ventilation systems and for downpipes inside civil and industrial buildings, hospitals and hotels.

It consists of three layers of material: the outer polypropylene layer provides high impact resistance and excellent mechanical protection.

The intermediate layer, consisting of a mixture of polypropylene and mineral fillers, is designed to further consolidate the structure of the pipe and, above all, determine the acoustic performance of the system.

Finally, inside the pipes, a final layer of polypropylene ensures excellent resistance to dissolved chemicals in civil and industrial drains, and has an extremely smooth surface to facilitate flow and prevent the accumulation of deposits.

The strengths of the system

Triplus is suitable for draining fluids up to 95°C. Its resistance to impacts and mechanical stresses is remarkable, even at very low temperatures (down to -25°C), making Triplus one of the most popular products in countries with colder climates.

The noise level is 12 dB with a flow rate of 4 l/s: we are talking about structure-borne noise, measured as prescribed by standard EN 14366.

Speaking instead of the eco-sustainability of the system, it should be emphasised that Triplus has obtained EPD certification, relating to the environmental performance of the product during its entire life cycle, from its manufacture to its disposal.

An extremely wide and versatile range

A distinctive aspect of the system is certainly the completeness and breadth of the range, consisting of pipes and fittings with an external diameter from 32 mm to 250 mm.

The pipes are produced in different configurations, with a socket to be inserted on one side only or on both sides of the pipe, and with lengths ranging from 150 mm up to 3 m, to cover every need and minimise waste.

The Triplus range is one of the widest available on the market, with specific solutions for needs that cannot be met by conventional fittings.

The wide variety of fittings - there are around 50 different shapes - is certainly a winning feature of Triplus; there are also fittings for passing to and from metal or different types of plastic pipes.

Finally, the range also includes solutions for special and complex requirements that cannot be met by conventional fittings.

The ventilation branch fitting

One example is the ventilation branch fitting, also known as the VBF; this is a special fitting that finds its ideal application in buildings of great height or characterised by a high contemporaneity factor in the use of sanitary devices. It was created with the objective of managing high flow rates, guaranteeing the correct ventilation of the system, while using a single pipe with a relatively small diameter.

Thanks to the particular conformation of this connection - which allows the slowing down of the discharge flow on each floor of the building, and to separate the inlet of the waste water coming from the horizontal branches from that passing through the vertical columns - the pressures generated can be considerably contained and, therefore, very high discharge capacities can be achieved without the need for a parallel ventilation column.

In this way, the number of sanitary appliances connected to the exhaust column can increase up to 6 times more (with the same diameter.

These features allow for a reduction in the overall dimensions of the drainage system, as well as the time and cost of implementation, with superior performance to traditional systems.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek