UNI 7129:2015 on the construction of indoor gas systems specifically indicates the possibility of using multilayer pipe systems. However, considering the many different types of installation and systems, the topic is of a certain complexity.

First of all, ‘internal installation’ refers to the set of pipes and related components (e.g. fittings, valves, etc.) that distribute gas from the meter to the user appliances.

It is important to emphasise, therefore, how multilayer systems, unlike other technical solutions, can actually be used to realise both the external part of the system and the part inside the building. This allows the installer to work with a single system, avoiding the need to install transition fittings or dielectric joints, thus reducing costs and simplifying the entire job.

A multilayer system is able to transport all the main gases; in fact, according to UNI 7129 the following are allowed:

- Family I gases (e.g. town gas)

- Family II gas (e.g. natural gas)

- Family III gases (e.g. liquefied petroleum gas LPG)

Let's then take a look at the different installations that are allowed according to the development of the installation, starting from the outside of the building up to the users.

TYPES OF INSTALLATION OUTSIDE BUILDINGS

According to UNI 7129:2015, multilayer systems can be installed outside buildings in the following ways:

- Underground

- In a gutter

- In a service slot

- In an underground technical shaft

The case we are going to investigate is the most common: a first part underground, from the meter to the wall of the building, then in a gutter up to the point where the wall itself is to be crossed.

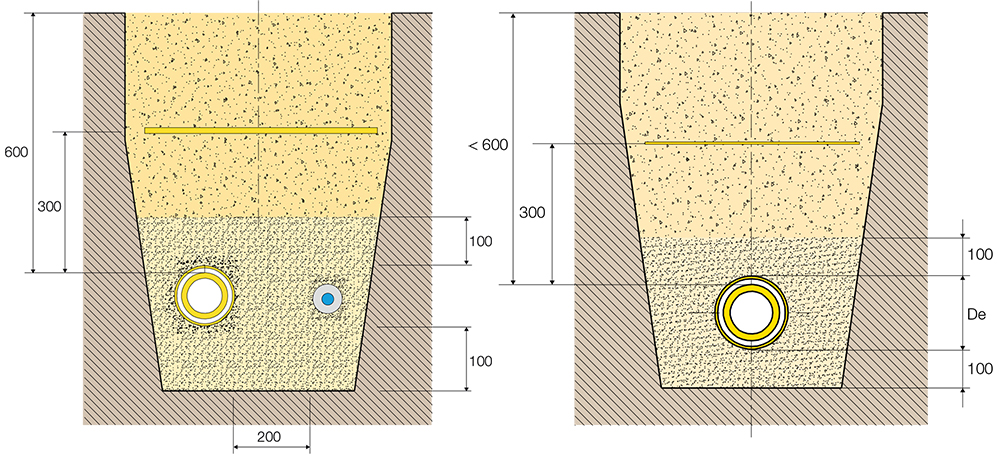

- The underground installation always requires the multilayer pipe to be protected by a sheath, which may be made of plastic material for underground installations below 600 mm, while it must be metal for burial below 600 mm. The pipe must be placed in a bed of sand or inert material with a reduced granulometry. A yellow warning tape must be placed 300 mm above the pipe. Any joints must always be protected against corrosion, e.g. by wrapping the connection with special tape. They can be buried or laid in an inspectable manhole.

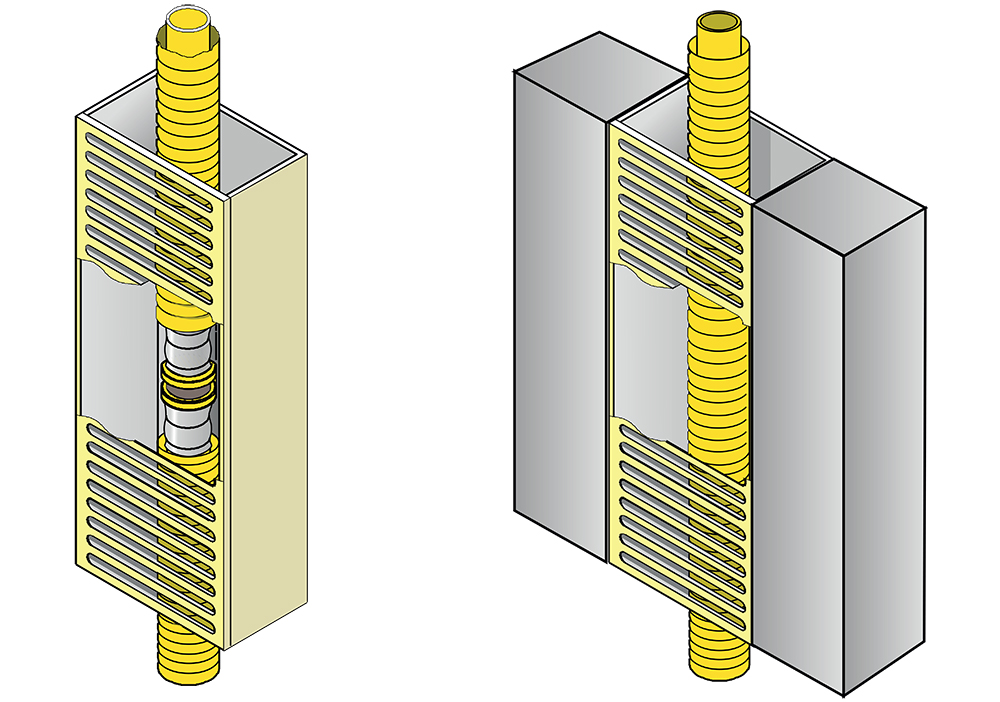

- Installation in a gutter: UNI 7129:2015 prohibits the visible installation of the multilayer pipe both inside and outside the building. Outside, however, it is possible to install the system in a grated or blind gutter; in the first case, the pipe must be protected with anti-UV sheathing, while in the second case it is not. The gutter may also be embedded in the masonry, thus avoiding any unsightly façade appearance.

TYPES OF INSTALLATION INSIDE BUILDINGS

Once through the perimeter wall, it is possible to move inside the building in the following ways:

- In a service slot

- In special housing

- Undercut

Considering that in Italy the most common type of building is masonry, we would like to provide all the indications for the installation below ground level, which is the most common case.

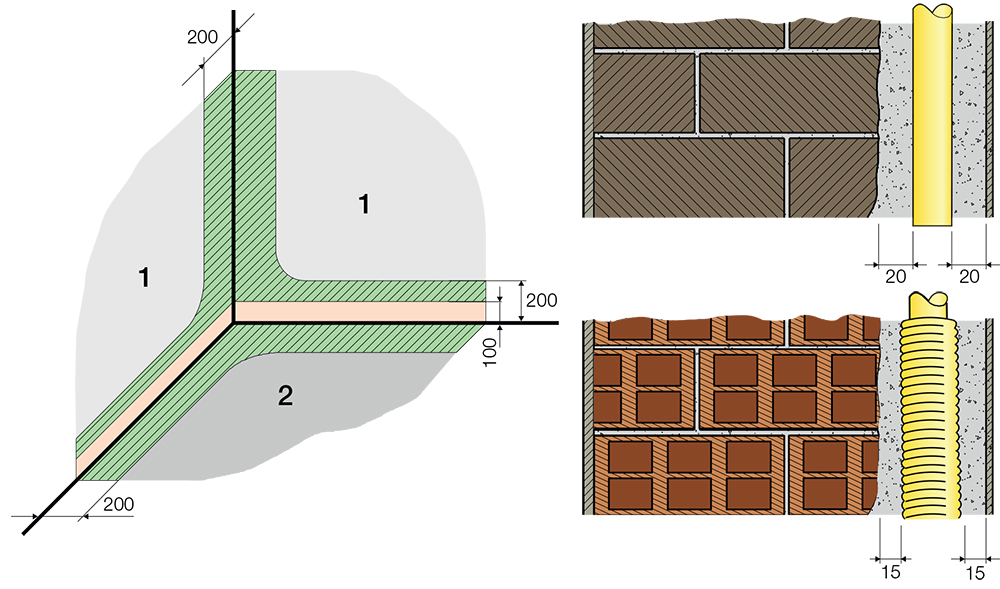

- Undercurrent installation of multilayer pipes is permitted in the building, in floors, in masonry, on the inside of perimeter walls as long as they run straight. The pipes must be laid parallel to the edges, at a distance of no more than 200 mm. If installed on the wall, it is better not to use the first 100 mm (where the skirting board is generally laid). If it is not possible to comply with this requirement, e.g. for the supply of an island hob placed in the centre of the room, the pipe must be laid perpendicular to the walls and its passage must be recorded by photographs, dimensioned drawings etc. documenting its position. As far as laying is concerned, the pipe must be embedded in cement mortar with a layer of at least 20 mm. If the walls contain cavities/cavities (e.g. walls made of perforated bricks), the pipe must be sheathed and in the event of leaks it will prevent gas from seeping into the cavities; in this case the minimum thickness of the cement mortar from the sheath is 15 mm.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek