AriaSilent sets itself apart from other systems on the market thanks to an approach designed to transform the Heat Recovery Ventilation system by simplifying the work of the designer and installer.

Among the innovations of AriaSilent are components made almost entirely of plastic, with anti-bacterial and anti-static features that help monitor and contain the spread of germs and bacteria in the environment: today we know for certain – especially thanks to recent studies and the media coverage the subject has received since the COVID-19 emergency – how the level of concentration of pollutants and harmful agents becomes something of concern when also considering the time we are exposed to them during our habitual presence in closed environments (a combination that makes it an actual health risk factor).

Unsurprisingly, we now talk about Heat Recovery Ventilation for many sensitive environments, in addition to the home, this latter, however, is where AriaSilent is focused with a solution suited to any installation, whether a new construction or a renovation.

AriaSilent system components

The AriaSilent system utilises double-walled corrugated ducts: round in sizes 63, 75 and 90 mm and oval in sizes 50x102 and 55x126 mm.

The pipes permit installation in the most widely varying contexts, as we said even where space is tight for new systems, a typical factor in building renovations. Thanks to this flexibility, the system can be installed with a minimum use of fittings.

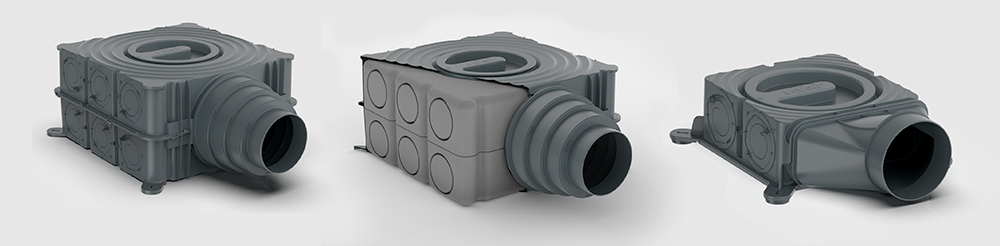

Another of the system’s key components are the distribution boxes, designed to ensure an optimal distribution of the airflows. Based on a patent (the flow divider, specifically), they are available in three versions:

- Standard, with a maximum of 18 connections

- Compact, with a thickness of only 11 cm

- Therm, with thermal insulation features to guarantee the combination with the air distribution system to HRV machines with dehumidification capacity and thermal integration

The greatest strength of the AriaSilent system is the optimisation of the components, which allows any installation to be realised with the use of very few items.

The boxes, which are also patented, have tear-off openings to allow for opening and using only the necessary connections. This component and the corrugated pipes are connected via AriaSilent Link universal fittings, one for each duct section, which are interchangeable and enable the same distribution box to be used regardless of the type of pipe or the combination of different sizes or types of AriaSilent Tube.

Also interchangeable are the grille holder vents: the idea behind this solution is to rationalise the number of components in order to maintain a high flexibility of installation thanks to the reduced amount of items required, regardless of the context.

Air quality is the main objective

AriaSilent is developed with anti-bacterial materials and technologies that enable a reduction in the presence of pathogenic agents in the distribution system, serving to improve the air quality and healthiness of the environments.

But the whole system has been developed with special focus on internal fluid dynamics for extremely silent operation and with the goal of achieving airflow rates and reduced pressure losses, this way increasing energy efficiency as well.

Airtightness is ensured by the installation of seals on AriaSilent Link fittings in compliance with the standard UNI EN 17192:2019 dedicated to the production of non-metallic systems to be used in building ventilation.

To sum up, the exceptional performance and outstanding technological content, complemented by the simplification of installation procedures, make the AriaSilent system an excellent choice when a change is needed, also from a marketing standpoint.

Italiano

Italiano

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Greek

Greek