In these cases, depending on the system requirements and restrictions, the following types of bracketing can be used:

- Bracketing with expansion socket.

- Bracketing with push-fit socket.

- Bracketing with expansion compensation.

- Rigid bracketing.

In relation to the type of bracketing chosen, so-called guide points and fixed points (or anchor points of the pipe) must be calculated. In all cases, if the waste system is required to reduce noise then sound reducing brackets with anti-vibration rubber must be used. If the waste system is constructed using Triplus® or Silere® then the use of sound insulating pipe brackets is essential.

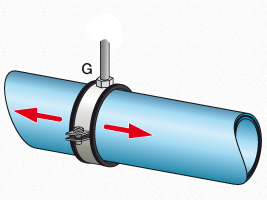

Guide points (indicated in the picture with the letter G) are created using brackets which, as well as supporting the weight of the pipe, they allow the axial movement of the pipe, preventing the pipe from flexing due to the increases in length caused by heat expansion, following increases in the temperature of the room and the waste water. Guide points are created when the bracket is not tightened completely around the circumference of the pipe, giving it free axial movement.

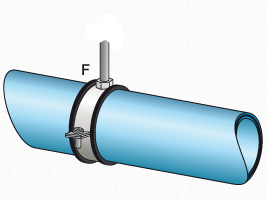

Fixed points (indicated in the pictures with the letter F) are also called anchor points and prevent any movement of the pipe in the area where the bracket has been fixed. The aim of fixed points is to divert the variations in length of the pipe in the desired direction, that is, towards the ring seal sockets, the expansion sockets or towards the compensation deflection arms. Fixed points are usually achieved by using suitable brackets that are closed tightly around the circumference of the pipe.

Guide points and fixed points must be calculated during the design phase according to precise rules, also in relation to the section of the system in question (stacks, collector pipes, branch-off points on the down-pipes, etc.). Bracketing is therefore a complex subject that needs to be dealt with in detail. Following this brief introduction, we therefore ask our readers to read up on this important subject, which is often undervalued, in the Valsir technical manual.