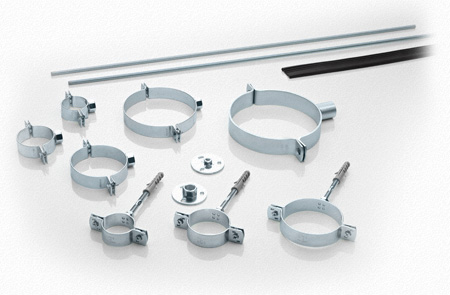

The bi-joint sleeve to reduce wastage to a minimum

To allow the use of leftover pieces of pipe, Valsir supplies a bi-joint sleeve. This is a special fitting that allows two pipes without sockets to be connected guaranteeing hydraulic tightness without compromising flow rates.

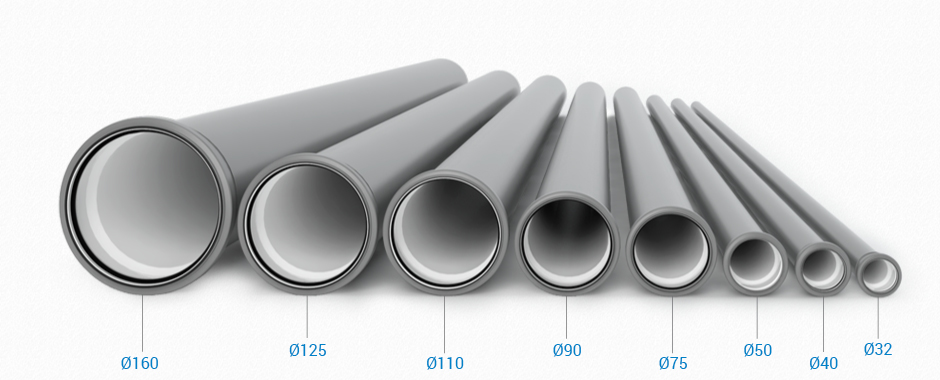

The EPD statement is available to certify the reduced environmental impact associated with PP3 according to the full life cycle assessment, or "cradle to grave". This means that our monitoring and optimisation efforts do not only cover the production stages: PP3 is a champion of sustainability from the extraction of its raw materials to the disposal of the product itself. Choose it for your project and get credits for Green Procurement sustainability protocols (e.g. LEED V4)!

The EPD statement is available to certify the reduced environmental impact associated with PP3 according to the full life cycle assessment, or "cradle to grave". This means that our monitoring and optimisation efforts do not only cover the production stages: PP3 is a champion of sustainability from the extraction of its raw materials to the disposal of the product itself. Choose it for your project and get credits for Green Procurement sustainability protocols (e.g. LEED V4)!