Not registered?

If you have not yet registered on the Valsir web site fill in the form with your details and obtain free access to the download area where you will be free to download our price lists and technical brochures. You will also have the possibility of receiving our periodic newsletter: the best way to remain up-to-date on all the latest developments in Valsir.

It was officially announced on Friday in Switzerland and we could not wait to announce it: Valsir® will be a Ducati sponsor also for the 2019 MotoGP Championship

On stage Andrea Dovizioso and Danilo Petrucci presented the new Desmosedici GP, a concentrate of technology, power and aerodynamics. Valsir will be back alongside Ducati for a championship to be experienced in one breath.

"The determination of the team to improve race after race, to always think in an innovative way and constantly seek new boundaries in technology is a perfect example of what Mission Winnow means," said Miroslaw Zielinski, President of the SME Science and Innovation Division.

The new Desmosedici GP has all the features to achieve important results. With a maximum speed of over 350 km/h and a weight of only 157 kg it releases a maximum power of over 250 CV.

In the saddle two great riders who will try to bring Ducati to the top of the standings.

Andrea Dovizioso

After finishing the last MotoGP season as runner-up for the second consecutive year, with four wins (Qatar, Brno, Misano and Valencia) and nine podiums overall (a personal record in the top class), Andrea Dovizioso is ready to challenge for the title once again, with even more experience under his belt. 2019 marks Dovizioso's twelfth season in MotoGP, and seventh in Ducati colours, where he will be joined by Danilo Petrucci.

Danilo Petrucci

Over the past four years with the factory-supported Pramac Racing Team, Danilo Petrucci enjoyed a steady growth as a rider. After showing promise in 2015 and 2016, he stepped up to the challenge by taking four podiums in the 2017 championship on a latest-spec Desmosedici GP machine, identical to the ones of the official riders: he was third at Mugello and Motegi, and second at Assen and Misano, finishing the season in 8th place with 124 points. Last year, the Italian took second place at Le Mans and, with 20 more points to his tally compared with the previous year, earned a position with the Ducati Team alongside fellow countryman Andrea Dovizioso.

It starts on Sunday 10 March in Losail, Qatar. The landscape will be the Losail International Circuit for a spectacular night race.

We and Ducati are ready to get on track with the mentality of all time: to give the maximum conviction that only by working together and taking care of every detail can you get great performances.

The air admittance valve is a useful solution to solve many problems related to waste systems ventilation. The aerator, during its functioning, balances the depressions created by the flow of fluids into the stack and the horizontal drainage branches and prevents bad smells emissions and noise formation, by taking air directly into the system in order to allow a proper waste system ventilation.

The international standards for waste systems inside buildings - such as UNI EN 12056 of 2001 - define the characteristics, the configurations, the design criteria and the sizing of the system. Standards are established for appropriate ventilation of waste systems and the minimum diameters to be used in relation to the units of waste. The same technical regulations involve the use of air admittance valves, provided that they are manufactured in accordance with the relevant construction standards. UNI EN 12380 of 2014, in fact, defines the classification, the requirements, the test methods and the declaration of conformity of the air valves of gravity waste systems.

Proper sizing and proper air ventilation of the waste system exclude the formation of hydrostatic pressures and depressions in the pipes, thus avoiding the bothersome noise of gurgle, the emptying of sanitary traps and consequently bad smells in the bathroom. The membrane aerator is a good solution in occasions where traditional techniques cannot be used. There follows a summary of the cases solved by installing the air admittance valve.

Architectural constraints or special weather conditions

Architectural constraints or special weather conditionsThe aerator can be used to ensure waste system ventilation when it is not possible to get air directly from the roof, for example, in the case of:

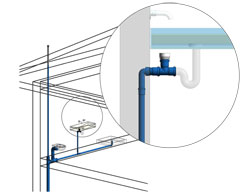

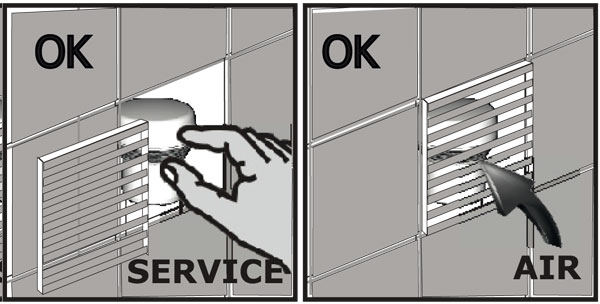

The solution in these cases is to install the aerator with membrane in the roof space or in a grid room where air is ensured (therefore the air valve cannot be walled), in order to facilitate the collecting of air from the air valve.

Insufficient or absent ventilation

Insufficient or absent ventilationThe air valve can be a very useful solution even in case of waste system malfunctioning caused by

In order to prevent the formation of unpleasant bubbling or hissing noise in the pipes and bad smells in the bathroom, it is possible to intervene directly on single traps and on the main waste pipe, by putting one or more specific air valves (e.g. under a washbasin or a sink).

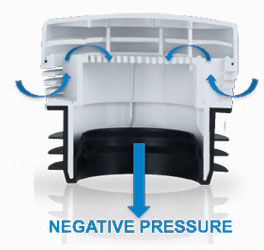

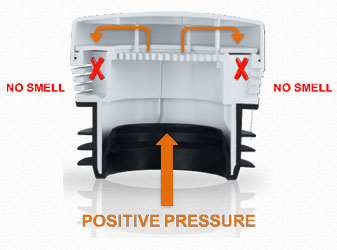

The air valve is equipped with an inner membrane that opens when negative pressures (e.g. during the drainage of wastewater) are created in the waste system, allowing the air to enter the pipe in order to balance these pressures. Then the membrane closes, avoiding the emission of bad smells.

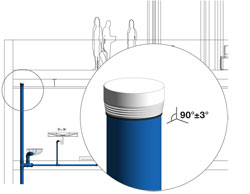

The air valve must be assembled in line with the column, so that the membrane can work in axis with the body of the valve (with a tolerance of ± 3 °); any horizontal installation is forbidden. The air admittance valve is placed inside a grid room or inside a false ceiling, where air is ensured. It is forbidden to lay the air admittance valve in rooms without air exchange (e.g. sealed in a niche).

For more information, please contact Valsir by sending an email to This email address is being protected from spambots. You need JavaScript enabled to view it. . We will be happy to provide you with the right advice

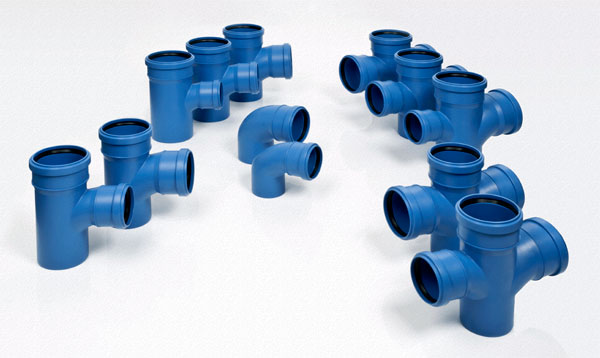

To respond better and better to the different needs of plumbers and designers paying great attention to the acoustic in waste systems, and at the same time requiring flexibility and ease of installation, the Triplus waste system adds 23 new figures of different diameters to its catalogue.

The Triplus® push-fit soundproof waste system welcomes in the range 23 new Triplus figures that will be available from July. The new range of fittings, which includes swept bends and single or double swept branches, is designed in different diameters to meet the many professional installation requirements. This means that Valsir has taken another step towards defining a range of push-fit pipes, fittings and joints for the soundproof waste systems that can clearly stand out - as well as for extremely high mechanical and acoustic performance - also in terms of range width and depth.

The Triplus waste water system list becomes even more complete mostly thanks to the addition of:

The 87°30' long radius bend represents an improvement in terms of performance if compared to the classic 87°30' bend: the system's acoustic performance and the waste outflow are increased. Therefore, it can be used in floor-to-wall connections, simplifying also video inspection.

In the absence of proper spaces in the installation at the foot of a column, the 87°30' long radius bend is a good alternative to the 90° bend, as, improving the outflow, ensures optimal performance of the system.

The 87°30’ sweep branch, single or double, is the perfect synthesis between the 87°30’ branch acoustic performance and the 45° branch flow rate. Using the double 87°30’ sweep branch, fewer fittings are needed in compared to the 45° branch, thus making waste systems building easier.

The performance of 90° and 180° ball branch, 2-way and 4-way, are half way between the ventilation branch fitting (VBF) and the 88° branch since, if compared to the classic solution, it ensures a largest mixing volume and, by limiting the size and number of fittings necessary for the system, increases the flexibility of the connection.

The performance of 90° and 180° ball branch, 2-way and 4-way, are half way between the ventilation branch fitting (VBF) and the 88° branch since, if compared to the classic solution, it ensures a largest mixing volume and, by limiting the size and number of fittings necessary for the system, increases the flexibility of the connection.

Triplus is the push-fit soundproof systemTriplus is the push-fit soundproof system that includes high-performance triple layer pipes, fittings and accessories that guarantees the low levels of noise emissions required by the regulations, laws and standards in force.

Triplus ensures practical and rapid installation without the use of glues, electrical appliances or special tools, thanks to the push-fit jointing system. The special geometry of the seal and the push-fit socket guarantee total water tightness and allow the normal movements of the pipeline including those caused by thermal expansion.

The introduction of new figures, within the already complete range of Triplus water drainage and waste systems, will allow an even wider choice of possible combinations for waste systems, while maintaining the excellent native acoustic characteristics and the performance you expect from a high-quality product.

For more information, please contact Valsir by sending an email to This email address is being protected from spambots. You need JavaScript enabled to view it. . We will be happy to provide you with the right advice.

The Winner S in-wall flush cisterns have been awarded the Best WELL rating for water saving: a useful help for plumbers, designers, architects and all customers in choosing the right WC flush system.

Drinking water: a resource threatened with exhaustion. In Europe, due to climate change and irregular nature of outflows, in certain periods of the year the total amount of water available decreases and can not meet the daily needs of all people. An increase in the demand of drinking water produces a rise in expenditure for water treatment and transportation and an increase in the energy needed to heat water.

Regarding the ecological strategy ongoing in the plumbing and heating sector, EUnited Valves (the association that represents the main European valve producers) has developed a new European classification system: WELL - Water Efficiency Labelling. Thanks to the WELL rating, the efficiency in terms of energy saving of the WC flush systems are immediately assessed by designers, architects, plumbers and end users.

It is important to know that the pre-condition to obtain the WELL certification is passing a strict approval process - in accordance with DIN EN 14055 and DIN 4109. The tests are performed in an accredited ISO 17025 laboratory only in the case of products with noise levels not exceeding 20 dB (A) with a pressure of 3 bars and noise levels not exceeding 25 dB (A) and a pressure of 5 bar (Class I). The test laboratory is the TÜV LGA which, following the approval assignment, carries out annual audits and inspections on the product, therefore in compliance with WELL requirements.

According to ISTAT, about 30% of the water consumption used in an average family goes away for flushing toilet (ISTAT, 2005). You can save a lot by implementing virtuous behaviors without compromising the functionality of the wc system. If we consider that a four-member household discharges the flushing toilet at least 12 times per day, the consumption of drinking water can be reduced by 68% using a 4-litre double flush cistern, using the minimum volume of water, as shown in the following table:

Example of potential water-saving

Water consumption for a 9-litre flush cistern:

12 x 9 l = 108 l/day

Water consumption for a 4-litre double flush cistern:

5 x 4 l = 20 l/day

7 x 2 l = 14 l/day

Water saving 74 l/day

For the purposes of the WELL classification and the assignment of related points, it is considered the unit of system composed by the flush cistern and the push plate. In this way, the single flush cisterns (without points for classification) can be equipped with a push plate and start/stop function (1 star) or double flushing (2 stars). With the latter, a saving rinsing is carried out that puts into circulation the exact amount of water needed for the cleaning activity.

Below is the table with the classification criteria:

| Rating criterion | Performed by | Rating |

| Volume/flush volume | Flush volume (fixed or adjustable) 6,0 l | |

| Flush volume (fixed or adjustable) 5,0 l or 4,0 l | ||

| Flush program | Undefined flush with minimum volumes | |

| Defined minimum volume flush |

Total: max. 4 stars

Water is an indispensable resource for existence and therefore needs proper management: this is one of the most important challenges of sustainable development. In recognition of this problem, Valsir is constantly committed to promoting careful and water-parsimonious use of water by producing efficient and environmentally friendly systems, which are respectful of the environment that is home to us.

Below is the WELL - Water Efficiency Label (the "home" category) assigned to the Winner® S in-wall flush cistern: a descriptive guidebook guide you in the reading of main features.

Look for the WELL label with Valsir and ask for more information. We will be happy to offer you the right advice.

This year Valsir won’t take part at MCE, Mostraconvegno Expoconfort. This choice was reached following deep reflection, considering the advantage of the participation to the exhibition as well as its usefulness for the typical visitor to be found at the stand. Considering the evolution of Valsir, the new products and the huge investments of the past years, we realized that today presenting Valsir in the narrow room of a stand - big as it may be - is no longer possible.

Valsir expands its Revit model range available for designers: in addition to TRIPLUS, SILERE, TROPEA S and ARIAPUR, the models of the HDPE waste system, as well as those of gullies and traps for bathroom systems are now available online.

HDPE is a weldable polyethylene system for high and low temperature waste plants, for waste systems ventilation and for siphonic rainwater systems inside and outside civil and industrial buildings. These new Revit models reflect the characteristics of ease of usage and design automation which can be found in the Revit families of the TRIPLUS and SILERE waste systems already available online.

The range of gullies and traps features various solutions proposed by Valsir, with models easy to be used and characterized by the possibility of combining the different accessories available, in particular:

VALSIR goes BIM, the planning process able to improve planning, construction and management of buildings.

The solid experience gained with noise – dampering systems has been applied to flush cisterns: in this way was born Tropea S, a new revolutionary flush cistern characterized by performance of excellence.

Tropea S boasts all the advantages of the previous cistern Tropea 3, with one very important aspect: silence. Tropea S is the first cistern in the world made of a soundproofing plastic material. Laboratory tests show that the perceived noise from Tropea S is 5 times lower as compared to the most-widely used in-wall cisterns on the market.

The triple layer polypropylene soundproof pipes and fittings system, TRIPLUS has obtained the Certificate of Conformity AENOR UNE EN 1451-1 “Plastic pipes for waste systems at low and high temperature inside buildings”.